Samalayuca II serves the one million population and over 300 factories in the region of Ciudad Juárez. Power will also be exported to the US. The plant was financed and built by a consortium on a build/lease/transfer (BLT) agreement. The purchasing consortium included El Paso, which in 2002 announced it was selling its 40% share.

The plant has been leased to CFE who is operating it for 20 years, after which outright ownership will be transferred to CFE. CFE is responsible for securing the fuel supply and the electrical transmission system.

SAMALAYUCA II PROJECT FINANCE

The Samalayuca II consortium partners each invested $132m, 20% of the total project cost. The four consortium members were originally GE, El Paso Energy, InterGen and ICA-Fluor Daniel.

The negotiations for the project took four years to complete and were not helped by the period of economic and political instability early in 1995.

The legal and financial obstacles were finally overcome in May 1996 and construction began. The first of the three gas turbines was commissioned in early 1998, followed by the second unit in summer 1998 and the final unit at the end of that year.

“The plant is now generating 700MW using dry combustion systems that limit NOx emissions to less than 25ppm.”

More than $638m was raised to finance the project, including $442m in non-recourse loans from four commercial banks, $75m in construction loans and ten-year term financing. The US Export-Import Bank provided $410m in political risk insurance and took out the commercial debt upon start up.

In 2002, El Paso announced it was selling its 40% share to an affiliate of GE Structured Finance, another project partner. In 2003, a merger between SFG XX Inc and Samalayuca Holding Partnership was authorised. The Holding Partnership now has as shareholders GE, SFG, and SAM II Generating Company (Cayman).

CCGT PLANT MAKE-UP

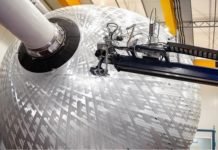

The Samalayuca II CCGT plant comprises three GE STAG 107FA gas-fired turbine modules, each with a heat recovery steam generator and a steam turbine. The system features an air-cooled condenser, as water supply is a problem in the region and the wells supplying the two Samalayuca plants have a restricted output. The condenser operates by passing the steam from the outlet of the steam turbine through finned tubes that are cooled by air currents. The plant consumes water at 6.3l per second, with a peak consumption of 60l per second.

Each of the consortium partners had a role in plant engineering and construction. GE developed the design concept and managed the overall project, as well as being the major equipment supplier. ICA was responsible for plant construction and national procurement. InterGen provided detailed plant design, engineering and construction management services.

The fourth partner, El Paso Energy, constructed the 38km pipeline to bring natural gas to the plant. This pipe meets the natural gas fuel requirement for Samalayuca II and adjacent existing plant of around 175MMcf/day.

GE 7FA SERIES GAS TURBINES

The 7FA series GE gas turbines work at 50% efficiency or above. They achieve high efficiency by operating at a high combustion temperature of 1,280°C, made possible by the application of advances in materials and cooling systems. The improved combined-cycle system also produces lower carbon-dioxide emissions, but nitrogen oxide (NOx) emissions tend to rise with higher efficiency.

To reduce NOx emissions, the 7FA gas turbines use precise sequencing and metering of fuel and air to burners in different locations in the combustion chamber. This ensures a leaner fuel/air mix a prerequisite for minimising NOx combustion products, which are kept below 25ppm. The Samalayuca II plant is designed to meet US emissions regulations for the El Paso region, as well as those set by Mexico’s environmental agency.

FUEL SUPPLY FROM NATURAL GAS PIPELINE

In the past, Mexico has used its abundant supply of oil to power electricity stations. However, Mexican crude has a high sulphur content and the utility has to import low sulphur oil to meet environmental restrictions.

“CFE operates over 37,500MW of capacity in Mexico and has a virtual supply monopoly.”

CFE is using natural gas for most new capacity it develops. It already operates a number of CCGT plants around the capital city, which has a reputation for poor air quality.

Each gas turbine consumes about 25kg per hour of natural gas. This is provided through a spur from the new Samalayuca–San Elizario pipeline. The plant can also be run on diesel oil if gas supplies are interrupted.

Mexico is the second largest electric power market in Latin America. CFE operates over 37,500MW of capacity and has a virtual supply monopoly. The Secretariat de Energia of Mexico published a report at the end of 1997, which forecast that Mexico would need to increase electric power capacity by 12,000MW by 2006. Privatisation laws allowing greater market access to Independent Power Producer (IPPs) were passed in the early 1990s. Samalayuca was the first major IPP project to be completed.

InterGen is operating or building a total of 20 power stations representing 16,220MW. ICA-Fluor Daniel is a joint venture between Mexico’s largest construction company, ICA, and US-based Fluor Corp.