A 450MW coal-fired power station has been built at Tarong North, next to the existing Tarong Power Station on the D’Aguilar Highway in Queensland, Australia. The project was built by an international consortium, and cost around A$650m.>

The project created 2235 direct and indirect jobs during construction, with an additional 170 permanent direct and indirect jobs over 25 years. After completion, Tokyo Electric Power Company (Tepco) and Mitsui bought a 50% stake in the power station from Tarong Energy.

Built by international consortium

The power station was built by an international consortium. IHI Engineering Australia Pty Ltd supplied the boiler and auxiliary equipment. Toshiba International Corporation Pty Ltd supplied the turbine, auxiliaries and plant control system. Pacific Power (International) Pty Limited was responsible for the rest of the power station, as well as construction coordination. Mitsui & Co Ltd provided project finance and financial services.

“When combined with a water-cooled condensing system, the ‘advance cycle’ reduces CO2 emissions by about 10%.”

On completion of Tarong North in August 2003, the Tokyo Electric Power Company and Mitsui bought a 50% stake (Tepco International holds 70% of the shares and Mitsui holds 30%). Tepco had at the time developed five overseas power generation projects in Taiwan, Vietnam, UAE and elsewhere.

Tepco and Mitsui jointly established TM Energy (Australia). This company and TN Power (a project company of Tarong Energy) together established the Tarong North Power Station Joint Venture. It is contracted for 20 years to sell all the generated power to Tarong Energy. Tarong Energy owns Tarong coal-fired Power Station and Wivenhow pumped storage hydro-electric Power Station (two units, 500MW). Its head office is in Brisbane.

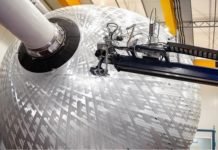

Supercritical boiler design for Tarong north

Tarong North uses advanced (supercritical boiler) technology. When combined with a water-cooled condensing system, the ‘advance cycle’ reduces CO2 emissions by about 10% compared with conventional coal-fired boilers. Supercritical boilers use higher steam pressures and temperatures than conventional plants like the existing Tarong Power Station, and so are more efficient.

Tarong North’s cooling towers are similar to those at Callide C, Swanbank, and Collinsville, rather than the large natural draft cooling towers used at the existing Tarong Power Station. The new towers are 243m long, 16m wide and 20m high. They use large fans to force air through a curtain of water droplets instead of the natural draft produced by the shape of the towers.

Uses same supply points as existing power station

Tarong North uses the same supply points as the existing Tarong Power Station for coal, fuel oil, hydrogen, demineralised water, drinking water, raw water, sewage, ash disposal, and cooling tower blowdown.

The existing coal handling plant at Tarong Power Station has two slot bunkers – A (for Units 1 and 2) and B (for Units 3 and 4). Slot bunker B now supplies coal to Tarong North. The new Coal Handling Plant is designed for future growth of Tarong North to a two-unit station. It has a capacity of 1000 tons per hour per route.

“The new Coal Handling Plant is designed for future growth of Tarong North to a two-unit station.”

Coal comes from meandu mine

Tarong Energy buys coal from Pacific Coal Pty Ltd (PCPL), having signed an agreement in late 1999. This secured a supply of coal from PCPL’s Meandu Mine to Tarong and Tarong North. When Tarong North came on line in 2003, approximately seven million tons of coal per annum was supplied by PCPL.

Tarong North is next to the 1400MW Tarong Power Station, one of Queensland’s largest. This is located on a 1500 hectare site near Nanango, west of Brisbane. The first of Tarong Power Station’s four generating units came on line in May 1984 and the station was completed in 1986. In all, the project employed more than 2000 people and cost more than $1.2bn to complete.