Project is part of reconstruction works at the facility

Technip has been awarded by Unipetrol a significant(1) lump sum contract to supply four cracking furnaces for their ethylene plant in Zaluzi, Czech Republic.

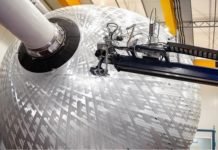

The project covers the engineering, supply and construction of the furnaces, including the associated pipe-rack. These new furnaces will replace damaged units at the site.

Two furnaces will be based on Technip’s proprietary SMK™ coil technology and the two others on Technip’s proprietary GK6® coil technology. During the last 10 years, SMK™ has been applied in more than 100 furnaces and GK6® in more than 76 furnaces.

The project will be executed by Technip’s office in Zoetermeer, The Netherlands, a center of excellence for ethylene technology.

Nello Uccelletti, President Onshore/Offshore, commented: “We are pleased that Unipetrol selected our furnace technology to help restore their ethylene plant into full operation. Our priority is to deliver this project safely and in accordance with the agreed fast-track schedule. This project strengthens our relationship with Unipetrol, following our recent award for a polyethylene unit”.

(1) For Technip, a “significant” onshore contract is ranging from €50 to €100 million.

Fast facts

About onshore products and technologies

Furnace: a furnace is an enclosed structure in which material is heated to high temperatures to produce ethylene and other products. This occurs in two sections. In the radiant section, the tubes receive heat through thermal radiation and the pyrolysis reaction (cracking) takes place. In the convection section, the flue gas is cooled to deliver high thermal efficiency by recovering the remaining heat.

Technip’s SMK™ coils enable selectivity optimization to obtain very large capacity furnaces with gas feeds. The largest capacity furnace in the world uses SMK™ technology and has a capacity of 210,000 tons per year of ethylene per furnace cell.

The GK6® coils are designed for liquids cracking with high selectivity for new furnaces and for the modernization of existing furnaces.