After around two years of construction, the Herdecke (North Rhine-Westphalia) plant began operation in October 2007. Statkraft owns 50% of the โฌ200m plant, with German energy company Mark-E owning the other half. The joint venture agreement gives both parties equal control of the company.

HERDECKE CONSTRUCTED BY SIEMENS

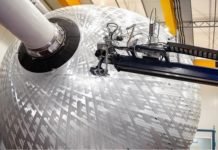

The plant was constructed by Siemens Power Generation as principal contractor. It supplied one gas turbine, one steam turbine and two generators. The output heat from the gas turbine flue gas generates steam using a heat recovery steam generator for the steam turbine. The Siemens combined-cycle plants (SCCs) combine the economic benefits of a pre-engineered power plant design with high flexibility through a wide range of options.

“After around two years of construction, the Herdecke plant began operation in October 2007.”

While the electrical efficiency of a simple cycle plant power plant without using waste heat typically ranges between 25% and 40%, a CCGT can achieve electrical efficiencies of 60% and more. Supplementary firing further enhances the overall efficiency.

HOT COMMISSIONING IN MAY 2007

The turbine was fired up in May 2007, followed by the ‘hot commissioning’ test period. This ‘first fire’ involved starting the gas turbine and running it up to neutral operation. It marked the start of operation, verifying that the gas supply, gas processing, control system and start-up system all worked together.

During the test period, the boiler was acid-washed to protect it against corrosion. The load on the gas turbine was then increased to test the generator and high voltage unit. Over the summer, steam production started in the boiler and electricity generated from both gas and steam turbines was gradually ramped up. Final performance was verified towards the end of the summer.

JOINT PROJECT BY MARK-E AND STATKRAFT

The Herdecke site has a 100-year history, with the first power plant appearing in 1908. Growing energy needs meant the plant was several times modernised and expanded. A 100MW H2 coal block supplied electricity from 1962 and was closed in 2004. Two natural gas cogeneration plants and associated hot water boilers were started in the same year. In that year, too, Mark-E started developing plans to construct the new Herdecke plant.

“Statkraft owns 50% of the โฌ200m plant, with German energy company Mark-E owning the other half.”

The plant is a joint project by energy service provider Mark-E Aktiengesellschaft (Hagen) and Norwegian company Statkraft AS (Oslo). Mark-E was responsible for project development and implementation.

Statkraft and Mark-E founded Herdecke (KGH) for operational management. A long-term supply contract for natural gas has been agreed with Wingas GmbH.

Mark-E now has a total generation output of around 1,200MW from hard coal, natural gas, biomass and hydroelectric power.

TWO STATKRAFT GAS-FIRED PLANTS FOR GERMANY

Herdecke was the first of two plants announced at similar times by Statkraft. The second was Knapsack, outside Cologne in the German state of North Rhine-Westphalia. Herdecke and Knapsack are important ‘door openers’ for Statkraft in Europe.

Knapsack is owned and operated by a Statkraft subsidiary established for the purpose. It is located in the Knapsack Chemiepark industrial estate, the site of many major industrial companies. The 800MW plant has a total annual output of between 4 and 5TWh and cost around โฌ400m.

The processes surrounding Knapsack and Herdecke were led by a German team, with project management and organisation also German. The process is being followed up by a combined team from both countries.

Statkraft also owns 50% of Naturkraft, which is building a 418MW gas-fired power plant at Kรฅrstรธ, Norway. The gas-fired power plants are part of the European quota system for greenhouse gases. The German plants primarily replace far more polluting coal power, typically 50% less CO2 and up to nine times less NOx.