Production Unit 3 was scheduled for a closure in 2013 after 45 years of service. A retrofit was proposed to extend the life of the unit by a further 30 years rather than decommissioning and constructing a new one.

The retrofit is currently underway and is being designed to allow the installation of a carbon capture and sequestration (CCS) equipment in future.

Integration of CCS will convert Unit 3 into a reliable long-term producer of 115MW of clean base-load electricity and simultaneously enhance oil production in the province. It will also reduce greenhouse gas emissions by capturing 1m tons of CO2 a year.

The CCS integration is one of the 30 projects that were endorsed by The Carbon Sequestration Leadership Forum (CSLF) in 2009. It is being executed by a public-private partnership (PPP) between the Government of Canada, Government of Saskatchewan, SaskPower and a number of private players. The government positions the CCS project as a demonstrator of sustainability in power plant technology.

“Integration of CCS will convert Unit 3 into a reliable long-term producer.”

Project finance

The Unit 3 retrofit will be self-financed by SaskPower. It is estimated to cost $354m including the turbine cost.

Installation of the CCS equipment is estimated to cost $1.2bn. The Canadian federal government committed $240m towards the CCS project in 2008.

History

SaskPower had initially decided to construct a 300MW plant to replace the aging Unit 3. Due to increase in the construction cost from $1.5bn to $3.8bn, the proposal was shelved and a much less expensive retrofit was considered.

The retrofit and CCS integration project was approved in 2008. The final decision to retrofit Unit 3 was taken in December 2010. Construction of the integrated CCS was, however, deferred until new federal regulations governing the thermal coal power generation emission controls are completed.

Development

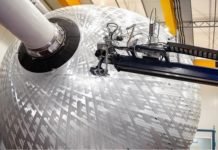

Unit 3 retrofit includes reduction of plant’s output from 139MW to 115MW. It will require replacement of the existing steam turbine generator with a new one that can be integrated with the CO2 and SO2 capture mechanism. The captured CO2 will be compressed and transported through pipelines to be sold for enhanced oil recovery. The SO2 will provide feedstock to a 50t per day sulphuric acid plant which will be built near the existing Unit 3.

A flue gas desulphurization (FGD) system will be placed to allow the installation of CCS equipment, which will reduce CO2 emissions by approximately 90%.

The flue gas will be treated and hydrated before being compressed and transported to oil fields. The treated flue will contain zero SO2 and just 10% CO2.

Cansolv’s FGD technology will integrate the SO2 and CO2 systems that will work in unison within a single plant.

Construction

The engineering, procurement and construction (EPC) contract for the CCS project was awarded to SNC-Lavalin and Cansolv Technologies in March 2010. The EPC contractor will be responsible for commissioning and start-up of the plant.

A $107m contract to retrofit the boiler was awarded to Babcock & Wilcox in January 2011. It calls for engineering and supply of all the critical components such as heat transfer surfaces and a new combustion system with low NOx technology.

“SaskPower had initially decided to construct a 300MW plant to replace the aging Unit 3.”

In February 2010, SaskPower signed a collaboration agreement with Hitachi to work on the advancement and implementation of CCS technology including the air quality control system, boilers and steam turbine generators. Hitachi Canada will also be supplying the custom-designed gas turbine.

Critical works of the main components commenced in early 2011. Physical construction of Unit 3 is expected to start in 2012 with completion scheduled in 2013.

Bidding process

SaskPower issued a request for proposals in 2008 for the CCS demonstration project. Flour Canada, Powerspan Corp and Cansolv Technologies were selected in the first stage.

Stantec Engineering, an independent consultant, evaluated the proposals based on performance, capital costs, operating costs, cost of capture and associated risks.

Cansolv Technologies was chosen as the preferred bidder in the first quarter of 2010.

For the supply of steam turbines, a two-stage procurement process was conducted. Of the seven vendors that were invited, Hitachi Canada won the bid.