The foundation stone for Barh I was laid in 1999 but it was doubtful at the time whether the project would ever be finished as the Bihar government was finding it difficult to make land available. The project had been delayed further by 36 months due to contractual disputes between NTPC and the initial contractor, Russian firm Technopromoexport (TPE).

It is believed that NTPC and TPE have come to an agreement for the timely delivery of Stage I after long negotiations. The Barh project is scheduled to be fully operational by August 2014.

“NTPC aims to add more than 10GW in new coal-fired plants by 2012.”

Barh II was announced in 2006 and is expected to be complete by January 2013; NTPC had earlier announced capacity enhancement for 2007-2012 from 11,558MW to 17,333MW, which included Barh II. Total cost of Barh I is Rs87bn of which Rs30bn has already been spent. Barh II is estimated to cost Rs73.41bn. The power will go mostly to North, West and East India. Six 400KV electrical substations link Barh to Kahalgaon, Sasaram and Biharsharif.

Barh I and II project details

India’s economic growth has put strains on its power supply capacity. NTPC was formed in 1975 to accelerate power development of the country, with the Government of India holding almost 90% of the company’s total equity shares.

Including Barh, NTPC plans to increase its installed capacity from the current 34,194MW to 75,000MW by 2017 and to 128,000MW by 2032. India’s Central Electricity Authority (CEA) cleared Barh I in 2001. The project was financed through domestic and external commercial borrowings, with equity from internal resources of NTPC.

As one of India’s mega power projects, Barh is eligible for benefits such as import of capital equipment free of customs duty, and price preference of 15% for domestic public sector undertakings (PSUs). It spreads over 3,200 acres of land, 98% of which is already acquired by NTPC.

Unit 1 of Barh I, which was supposed to be commissioned in March 2009 is now scheduled to operate in 2012.

Units 1 and 2 of Barh II are scheduled to commission in March 2012 and January 2013 respectively.

Power will be transmitted to the national grid by Power Grid Corporation of India (PGCIL).

Contracts

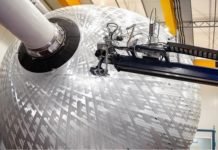

The plant uses super-critical steam generation, with water instantly being converted into steam without passing through the boiling phase. Operating pressures are around 250 atmospheres.

For Barh I, NTPC awarded the contract to Russia-based power equipment supplier, Technopromexport. The group is responsible for the design, manufacture, supply, building and commissioning of the three power units for the turbine island. Equipment for each machine is being manufactured at Leningradsky Metallichesky Zavod (steam turbines), Electrosila (turbogenerators) and Kaluga Turbine Works (feedwater turbine-driven pumps).

The KSB Group produced 18 pump sets consisting of nine turbine- or electric-driven boiler-feed pumps and nine condensate pumps. The biggest pump sets have a drive rating of 18,000kW each and generate a discharge pressure of 320bar.

Yokogawa India will supply the turnkey automation and control system for the boilers and associated equipment of three power generators. These include the CENTUM CS 3000 R3 distributed control system, PRM plant resource manager, DPharp EJA pressure/differential pressure transmitters and IR8A infra-red gas analysers.

The annual coal requirement for Barh is estimated at around 15 million tons per annum, met from theAmrapali block of North Karanpura coal fields. NTPC transports coal by rail from North Karanpura to Barh.

“The annual coal requirement for Barh is estimated at around 15 million tons per annum.”

In order to reduce up to 30 million tons of coal consumption over a period of 25 years, NTPC is adopting ultra-supercritical technology to increase the cycle efficiency of its power plants. The new ultra-supercritical technology will reduce carbon emissions up to 33 million tons a year. The technology is being provided by ABB for phase II of the Barh project.

The Indian state-run Bharat Heavy Electricals Ltd (BHEL) will be supplying the boilers for BarhII, partnering with Alstom and Siemens. Ansaldo Coldaie had also wanted to bid for the Barh II contract, but reportedly could not meet key technical conditions.

In May 2010, Mistsubishi Heavy Industries (MHI) and BHEL jointly won the order to supply 18 pumps for units 1 and 2 of 1,320MW Barh II project. They are expected to be delivered in 2011.

Environment concerns in Bihar

Wildlife Week reported complaints that Barh would impact the Taal wetlands, which are extremely rich in avifauna. The Barh project was cleared by the Ministry of Environment and Forests (MoEF) in 2001.

Ornithologists have, however, counted 149 species of resident and migratory water birds in the wetlands, which is an important bird breeding site.

The area is close to the Important Bird Area (IBA) of Kanwar Lake Bird Sanctuary. Wildlife Week accused the MoEF of hurriedly pushed the project through, without heeding high-level advice that a bio-habitat analysis be first conducted as the existing environmental impact assessment was inadequate.