Stage one was completed in March 2006. The second unit was put into commercial operation in February 2007. The combined output of the two units is 280MW of sent out electricity and up to 840t/h of high-pressure steam.

Alinta owns and operates the facilities which run 24 hours / day. Compared to a same footprint coal fired plant, the two cogeneration units can save around 900,000t of greenhouse gas emissions a year. The plant also reduces Alcoa’s refinery emissions by 270,000t a year.

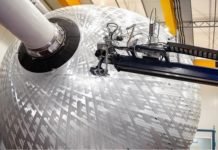

Cogeneration units: GT and HRSG

“The cogeneration unit is one of Western Australia’s most energy efficient power plants.”

The cogeneration units are built on a 2.5ha site within Alcoa’s Pinjarra Alumina Refinery, about 6km east of the town of Pinjarra. The site is immediately south of the refinery’s existing gas-fired powerhouse and adjacent to the refinery’s natural gas supply pipeline and a Western Power 132kV substation.

The cogeneration unit is one of Western Australia’s most energy efficient power plants. Waste heat from the gas turbines generates steam for Alcoa’s Pinjarra refinery and Alinta supplies power at lower cost to customers within the South-West Interconnected System (SWIS).

Alcoa’s Pinjarra refinery produces 4.2 million tons of alumina per annum, representing about 7% of the world’s alumina refining capacity. This capacity was achieved after completion of an upgrade to the alumina plant in 2006 at an investment of $805m.

Aluminia production takes heavy energy input

The bauxite recovered from the Darling Range is of a low quality. For every three tons of bauxite mined, only one ton of alumina is recovered. This means more energy has to be used to remove the alumina from this low-grade ore than at refineries with higher grade ore. The Pinjarra refinery uses three forms of energy in the alumina refining process: natural gas, steam and electricity.

The annual net average CO2 emissions from the cogeneration unit at Pinjarra are estimated to be 474,500t. The efficiency upgrade and the Alinta cogeneration projects have cut greenhouse gas emissions by approximately 15% a year.

Cogeneration allows throttling back of existing gas-fired boilers

Alcoa’s steam generation facilities at Pinjarra consisted of six gas-fired boilers, which produced an average 910t/h of high-pressure steam. The cogeneration facilities provide steam more efficiently (more than 80% efficient compared with 25% to 50% for other power plants operating in WA) and at lower cost. The steam produced by each cogeneration facility replaces the requirement for 240t/h of high-pressure steam previously generated by the refinery’s boilers.

The new gas turbines use dry low-NOx burners to achieve emissions of less than 25ppm(v) NOx (expressed at 0°C, 1,013.25hPa, dry and 15% O2) during normal operations, as required in EPA Guidance Statement No.15 (EPA, 2000).

“Alinta’s natural-gas-fired cogeneration facility is located in Alcoa’s Pinjarra Alumina Refinery in Western Australia.”

Heat from the turbine exhaust gases produces high-pressure steam in the HRSG unit. When a gas turbine is operating at loads less than 100%, the HRSG is fired using additional supplies of natural gas to maintain 240t/h steam output.

Cogeneration units 1 and 2 supply just less than 50% of the refinery’s current steam requirements, thus permitting a substantial ‘throttling back’ of the existing boilers. The improved efficiency is resulting in a net annual reduction in greenhouse gas emissions associated with steam production of some 150,000t CO2 for the two units.

Using refinery ‘cold’ condensate in the HRSGs instead of the refinery boilers also allows the existing boilers to be supplied with hotter condensate. This reduces the steam needed to heat boiler feedwater and the steam can be used elsewhere in the refinery process, further increasing efficiency.

The two cogeneration units have reduced steam demand from the existing refinery boilers by 4% to 5% – a further annual reduction of approximately 90,000t of CO2.

Automated, integrated control

The cogeneration units have been automated and integrated into the refinery powerhouse’s existing distributed control system. The units ‘load follow’ customer requirements and operate at between 85% and 100% capacity on a daily basis.Power is generated at 15kV then stepped up to 132kV through an on-site transformer.

Natural gas distribution and retail

Alinta distributes and retails natural gas in Western Australia, currently delivering natural gas to over 580,000 customers. The cleaner and cheaper electricity produced by the cogeneration plant is an important part of Alinta’s move into competing for business and industrial customers.

Alcoa produces primary aluminium, fabricated aluminium and alumina. The company is active in all major aspects of the industry including technology, mining, refining, smelting, fabricating and recycling.