Blyth offshore wind farm was opened in December 2000, and the plant has been producing enough clean and renewable electricity to power 3,000 average households ever since. The turbines were manufactured by Danish wind energy company Vestas, and installed by the marine division of AMEC Capital Projects and Seacore.

PROJECT MAKE-UP

Blyth Offshore Wind Limited consortium comprises Border Wind, PowerGen Renewables (a joint venture between Abbot Group and PowerGen), Nuon UK and Shell Renewables. The UK is one of the windiest countries in Europe and theoretically has enough offshore wind to supply three times the UK’s current electricity requirements. UK companies have the potential to be fully involved in the manufacturing and installation of offshore wind farms. In a recent consultation document published by the Department of Trade and Industry (DTI), the installation of more than ยฃ6 billion worth of offshore wind farms around the UK was suggested.

The ยฃ4 million project has received financial support from the European Commission Thermie Programme. It is being monitored and evaluated as a part of the DTI’s Wind Energy Programme, which aims to enable offshore wind power development and to support UK industry.

WIND TURBINES

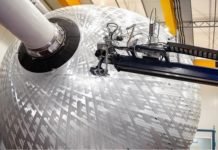

The two wind turbines are erected 1km off the coast of Blyth, Northumberland, close to the existing Blyth Harbour wind farm in an average water depth of 8m. The 2MW V66 turbine features a rotor diameter of 66m, hub heights of 60m to 78m, and uses an OptiSpeed system, which allows the turbine blades to rotate at variable speeds.

With OptiSpeed, the revolution speed can now vary by up to 60%. The OptiSpeed converter only transforms the energy from the generator rotor, which is only a small part of the total energy generated by the system. The energy generated by the generator rotor is converted back into electricity suitable for the grid by the converter. The standard setting of the turbine prevents it from receiving reactive output from the electricity grid.

TURBINE CONTROL

The V66 is equipped with microprocessor-controlled pitch regulation, which ensures continuous and optimal adjustment of the angles of the blades in relation to the prevailing wind.

The turbine’s systems make it possible to optimise the often contradictory requirements for high output and low sound levels, depending on the location. On the V66 turbine, the pitch mechanism is fitted in the blade hub itself and contains a separate hydraulic pitch cylinder for each blade. These separate pitch cylinders also ensure triple braking safety, because one feathered blade is sufficient to stop the turbine.