GE (NYSE: GE) today announced it is helping the Electricity Generating Authority of Thailand (EGAT) upgrade its fleet of four GE 9F gas turbines at the Authority’s two power plants. As a result, EGAT is improving the operational and fuel flexibility of the plants while significantly reducing emissions to improve air quality in Bangkok and the surrounding area. EGAT is Thailand’s leading state-owned power utility and largest power producer.

“By working with GE to increase the flexibility and efficiency of our power plants at EGAT North and South Bangkok, we are strengthening power security for our country in the event of different gas compositions (WOBBE INDEX) while also improving air quality and reducing fuel consumption,” said Mr. Charin Kanjanarat, EGAT Assistant Governor—Generation 1. “Energy efficiency and environmental protection are priorities that support Thailand’s growth policies, and we implemented strong measures to reduce and control our environmental impact. One change is already visible: the power plants are currently operating at 9ppm NOx, resulting in an increasingly cleaner environment for Thailand’s residents.”

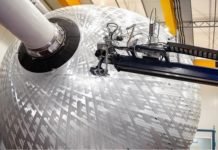

By upgrading the gas turbines to GE’s Dry Low NOx 2.6+ (DLN2.6+) combustion hardware and OpFlex* AutoTune optimization software, the units can reliably run on a wider range of natural gas compositions, including gas from both western and eastern Thailand. This gives EGAT better operational flexibility with its power plants, providing the country with more secure power generation capacity by enabling future gas supplies come from different sources, including imported LNG.

For EGAT North Bangkok Block I, the project also includes installing GE’s Advanced Gas Path (AGP) solution in 2016 to increase power plant efficiency. The AGP technology will allow EGAT to enhance efficiency, reduce fuel consumption costs, expand the flexibility of the operating window with improved turndown rate and extend turbine availability with the industry’s longest gas path maintenance interval. Collectively, these measures both increase the reliability of the power supply and reduce electricity costs.

“After working closely with EGAT’s team to develop cost-effective, tailored solutions, GE is delighted to upgrade EGAT’s gas turbine assets with solutions that harness the combined power of hardware innovations, advanced software and data analytics. They will play an important role in helping EGAT continue to deliver world-class performance in terms of reliability, environmental benefits and cost-effective results,” said Ramesh Singaram, president of Power Generation, Asia Pacific, GE Power & Water. “Blending these technologies provides EGAT even more robust operational flexibility and improved ability to respond to dynamic power grid conditions while continuing to further reduce its environmental footprint for the Thai people. This project underscores the opportunity utilities and other industries around the world have to modernize their power generation equipment, improve plant flexibility and economics.”

EGAT implemented the upgrades as part of its commitment to adopt sound environmental technologies to control its emissions. As a result, EGAT has improved air quality in the capital city of Bangkok by dramatically reducing the power plants’ NOx emissions from 35 ppm to 9 ppm.

The AGP, DLN 2.6+ combustion and AutoTune solutions are all part of GE’s broader Power FlexEfficiency* portfolio that delivers a suite of hardware and software-blended solutions to allow operators of existing GE F-class gas turbines to achieve continued optimal performance and long-term value of their existing assets. In addition to offering greater fuel flexibility, GE’s DLN2.6+ combustion system reduces NOx emissions to stay within permit levels and meet strict regulatory requirements.

GE’s advanced OpFlex* AutoTune suite of software solutions are a GE Industrial Internet offering aimed at boosting the performance and life of existing gas turbines and power plants without performing a major outage, allowing operators to reduce their costs and maintain regulatory compliance.