Smart Cable Management for Next-Generation Power Plants

The evolution of power generation technology has reached a critical juncture where traditional cable management approaches are no longer sufficient to meet the demands of modern facilities. Smart cable management power plants are emerging as the new standard, integrating advanced monitoring technologies, artificial intelligence, and predictive maintenance capabilities that fundamentally transform how power generation facilities operate and maintain their electrical infrastructure. The integration of intelligent systems with robust cable protection creates comprehensive solutions that optimize both operational efficiency and long-term reliability while reducing maintenance costs and system downtime.

The Digital Transformation of Power Plant Infrastructure

Intelligent Infrastructure Evolution

Modern power plants are undergoing a comprehensive digital transformation that extends far beyond generation systems to encompass every aspect of facility infrastructure, including cable management systems. This transformation recognizes that reliable electrical infrastructure forms the foundation upon which all other plant systems depend. The integration of smart technologies into cable management systems enables real-time monitoring, predictive maintenance, and automated optimization that were previously impossible with conventional approaches.

The development of intelligent cable routing systems represents a fundamental advancement in power plant design and operation. These systems utilize advanced sensors, communication technologies, and analytical capabilities to provide continuous assessment of cable health, environmental conditions, and system performance. This comprehensive monitoring capability enables maintenance teams to identify and address potential issues before they result in costly failures or safety hazards.

Smart cable management systems now incorporate machine learning algorithms that analyze operational data to identify patterns and predict potential problems with unprecedented accuracy. These systems learn from historical performance data, environmental conditions, and maintenance activities to develop predictive models that optimize both performance and maintenance scheduling.

Advanced Monitoring and Diagnostic Capabilities

Real-Time Cable Health Assessment

Modern smart cable management systems utilize distributed sensing technologies that provide continuous monitoring along entire cable runs, enabling detection of developing problems before they become critical. Fiber optic distributed temperature sensing (DTS) systems can monitor cable temperatures with one-meter resolution every ten seconds, providing immediate detection of hotspots or thermal anomalies that could indicate developing problems.

Advanced monitoring systems now integrate multiple sensing technologies including temperature monitoring, vibration detection, partial discharge monitoring, and strain measurement to provide comprehensive assessment of cable health. This multi-parameter monitoring approach enables detection of diverse failure modes including thermal stress, mechanical damage, insulation degradation, and environmental damage.

The integration of distributed acoustic sensing (DAS) capabilities enables detection of mechanical disturbances, tampering attempts, and developing structural problems that could affect cable integrity. These systems utilize coherent optical time domain reflectometry to detect even minor vibrations and acoustic events along cable routes, providing security monitoring alongside condition assessment.

Predictive Analytics and Machine Learning

Artificial intelligence and machine learning technologies are revolutionizing how power plants approach cable system maintenance and optimization. Advanced analytical systems can process vast amounts of sensor data to identify subtle patterns that indicate developing problems long before they become apparent through conventional monitoring approaches. These systems continuously learn from operational experience, improving their predictive accuracy over time.

Predictive maintenance algorithms analyze multiple data streams including temperature variations, electrical performance parameters, environmental conditions, and historical maintenance records to develop comprehensive assessments of cable system health. These systems can predict component failures weeks or months in advance, enabling maintenance teams to schedule repairs during planned outages rather than responding to emergency failures.

The integration of digital twin technologies creates virtual models of cable systems that enable sophisticated analysis and optimization approaches. These digital representations combine real-time sensor data with detailed system models to simulate various operating scenarios and optimize system performance under diverse conditions.

Smart Infrastructure Integration and Automation

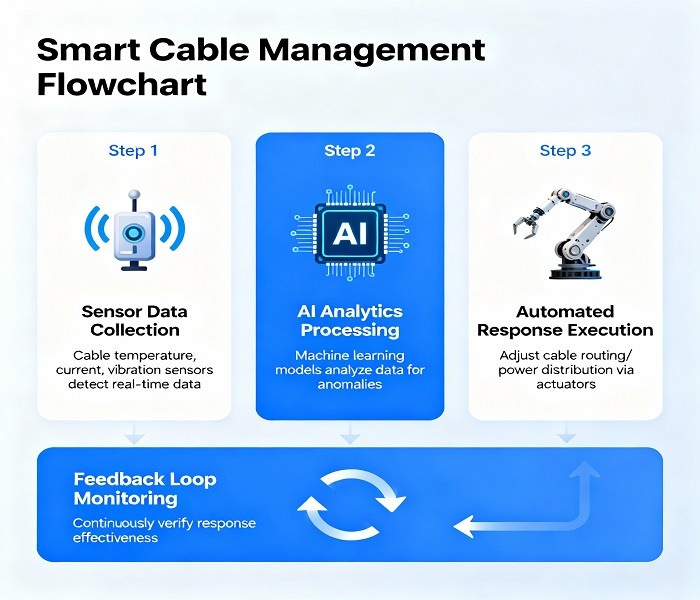

Automated Response and Control Systems

Smart cable management systems increasingly incorporate automated response capabilities that can adjust system parameters or isolate problems without human intervention. These systems can automatically modify cooling systems, adjust load distribution, or isolate damaged cable sections to prevent problems from escalating into major failures. The integration of automated response capabilities with comprehensive monitoring creates self-managing systems that optimize performance while minimizing risks.

Advanced control systems now enable dynamic cable rating that adjusts power transmission capacity based on real-time environmental conditions and cable temperatures. This capability allows power plants to maximize transmission capacity during favorable conditions while ensuring that thermal limits are never exceeded, optimizing both performance and safety.

The development of smart grid integration capabilities enables cable management systems to coordinate with broader power system operations, optimizing power flow and reducing stress on critical components. These systems can automatically adjust operations in response to grid conditions, renewable energy fluctuations, and demand variations.

Internet of Things (IoT) and Edge Computing

The proliferation of IoT technologies in power plant environments enables unprecedented levels of monitoring and control granularity. Smart sensors deployed throughout cable systems provide continuous data streams that enable detailed analysis of system performance and condition. These sensors can monitor parameters including temperature, humidity, vibration, electrical performance, and environmental conditions.

Edge computing capabilities enable real-time processing of sensor data directly within cable management systems, reducing communication requirements while enabling rapid response to developing problems. These distributed processing capabilities ensure that critical safety functions can continue operating even if communication with central control systems is interrupted.

The integration of wireless communication technologies reduces installation complexity while enabling monitoring in locations where wired connections would be impractical. Advanced wireless protocols provide reliable communication even in the electromagnetically challenging environments typical of power generation facilities.

Enhanced Safety and Reliability Systems

Advanced Fault Detection and Prevention

Smart cable management systems incorporate sophisticated fault detection capabilities that can identify developing problems long before they pose safety risks. Partial discharge monitoring systems can detect insulation degradation in its earliest stages, enabling replacement before dangerous conditions develop. These systems utilize advanced signal processing techniques to distinguish between normal electrical noise and genuine partial discharge activity.

Arc fault detection systems specifically designed for power plant environments provide early warning of developing electrical faults that could lead to fires or equipment damage. These systems utilize advanced algorithms to distinguish between normal switching operations and dangerous arc fault conditions, enabling rapid isolation of affected circuits.

The integration of environmental monitoring capabilities enables smart cable management systems to detect conditions that could affect cable performance including chemical exposure, moisture ingress, and temperature extremes. Early detection of these conditions enables preventive action before cable performance is affected.

Cybersecurity and System Protection

Modern smart cable management systems incorporate comprehensive cybersecurity measures that protect against both accidental interference and malicious attacks. These systems utilize encrypted communication protocols, access control systems, and network segmentation to ensure that critical infrastructure remains secure. The integration of cybersecurity capabilities with operational technology creates defense-in-depth approaches that protect against diverse threats.

Advanced authentication and authorization systems ensure that only qualified personnel can access or modify cable management system configurations. These systems maintain detailed audit trails of all system interactions, enabling rapid identification of any unauthorized activities or configuration changes.

Installation and Integration Considerations

Modular and Scalable System Design

Modern smart cable management systems utilize modular design approaches that enable customization for specific power plant requirements while providing scalability for future expansion. These systems can be deployed incrementally, starting with critical cable runs and expanding to encompass entire facilities over time.

The development of standardized communication protocols and interfaces enables integration of smart cable management systems with existing plant control and monitoring systems. This compatibility ensures that new technologies can be deployed without requiring complete replacement of existing infrastructure.

Advanced mounting and installation systems reduce deployment time and complexity while ensuring robust physical protection for monitoring equipment. These systems accommodate diverse installation environments including underground conduits, overhead cable trays, and buried direct installations.

Future-Proofing and Technology Evolution

Smart cable management systems are designed to accommodate future technology developments through modular architectures and standardized interfaces. This approach ensures that systems can be upgraded and enhanced as new technologies become available without requiring complete replacement. The integration of artificial intelligence capabilities enables systems to improve their performance continuously through machine learning and operational experience.

The development of self-healing cable technologies represents the next frontier in smart cable management. These advanced systems will automatically repair minor damage while providing notification of maintenance requirements, further reducing maintenance costs while enhancing reliability.

Economic Benefits and Performance Optimization

Operational Cost Reduction

Smart cable management systems provide significant operational cost reductions through optimized maintenance scheduling, reduced emergency repairs, and extended equipment lifespans. Predictive maintenance approaches enable maintenance activities to be scheduled during planned outages, eliminating the costs associated with emergency shutdowns and repairs.

Energy efficiency optimization through intelligent cable management can reduce power plant auxiliary consumption while maximizing generation capacity. These systems identify opportunities to reduce losses and optimize power flow, directly improving plant profitability.

Enhanced Plant Availability and Reliability

The integration of smart cable management systems significantly improves power plant availability by preventing unplanned outages and reducing maintenance downtime[66][72]. Advanced monitoring and predictive maintenance capabilities enable problems to be identified and addressed before they result in forced outages.

Improved reliability through smart cable management enhances both safety and economic performance while supporting power system stability[61][67]. These systems contribute to grid reliability by ensuring that power plants can operate consistently and respond effectively to grid requirements.

The future of power generation will be characterized by increasingly sophisticated integration of smart technologies throughout all aspects of plant operation. Smart cable management systems represent a critical component of this evolution, providing the foundation for reliable, efficient, and safe power generation in an increasingly connected and automated world. As power generation technologies continue to evolve toward greater efficiency and environmental sustainability, smart cable management will remain essential for achieving these objectives while maintaining the reliability and safety standards that modern society demands.