India’s Current Power Scenario

The energy landscape is changing fast. Despite the global transition towards renewable power, technologies for cost-effective power are still needed. Since coal-based power is not going to disappear for decades to come, technocrats are looking to make new high-efficiency power plants and operate existing power plants more efficiently and deliver cleaner energy.

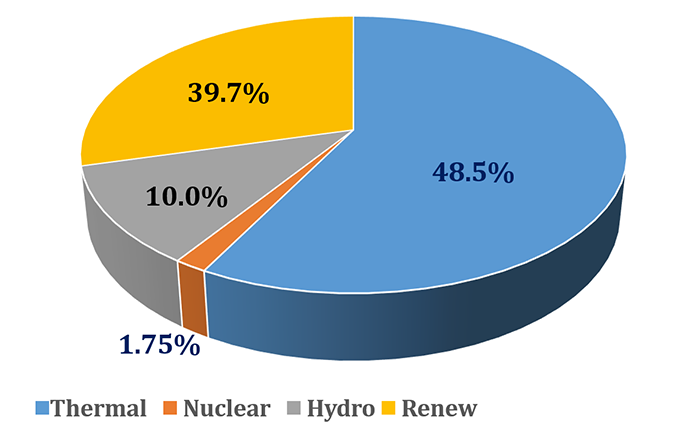

Today 40% of the world’s electricity is produced from coal-fired plants. Regardless of each country’s unique balance, coal will remain part of the long-term electricity strategy. In India, the current total installed capacity of coal-fired power plants is greater than 48%. The private sector has installed nearly 38% of the total thermal power capacity and electricity is being generated with an average capacity factor of 65-70% from coal-fired power plants.

Refer Chart 1. The installed renewable energy capacity is reaching over 39 per cent. Government of India forecasts have said India plans to increase its coal power capacity by 60% over the next decade, from 250 GW currently operating to 330 GW by 2035. That includes a target of at least 80 GW of new coal-fired generation by 2032. The country also has a goal of producing at least 500 GW of power from renewables and other non-fossil fuel sources by 2030, which is more than twice the current level of 200 GW.

India Ratings & Research, an agency that offers credit rating and research services in that country, said the latest bids come after more than 17 GW of coal-fired generation capacity has been contracted over the past year-plus through July of this year. The group said it’s the largest amount of coal generation contracted in the past few years, or at least since the Covid pandemic depressed activity earlier this decade.

Energy analysts have said India’s increased need for electricity, driven by a growing economy, higher demand for air conditioning, and more electrification of industry & rural areas, along with more people gaining access to electricity, means coal will continue to play a major role in the country’s power generation. Analysts have said that’s also due in part to a slower buildout of cleaner technologies such as battery energy storage and the need for baseload power to balance the increased use of renewable energy.

The resultant flat or low load demand has caused the operations of many base load coal-fired power plants to become cyclical in nature. Coal-fired power plants have adapted to the requirements of frequent unit shut-downs (RSD), higher ramp rates, cyclic operations, increased lay-ups, and prolonged periods of low load or technical minimum operation.

To meet the changing market conditions brought about by increasing renewable energy sources, coal-fired power plants need to improve their flexibility and operating practices specifically to operate at less than 45-50% continuous rating (TMCR) load for short periods or daytimes. Power-generating companies must identify and prioritize opportunities to improve coal-fired units based on their expected returns and the impact of operating at low loads or technical minimums on their business objectives.

Installation of Efficient Coal Power

Rapid urbanization and the need for meeting rural electrification mean the coal power capacity factor should increase further to the 70–80% level and continue to play a key role for the next decade. Supercritical technology or larger-sized units partially addresses the emissions requirements; however, large investments or an increased tariff structure are needed to comply with stringent emission controls such as SO₂, NOx, and CO2, and these emissions lead to global warming. This article is also focused on supercritical or ultra-supercritical technology only for evaluation purposes. The typical installation cost of this coal-based supercritical technology ranges from Rs. 6 Cr to 7 Cr per MW with half or one acre of land per MW for 660 MW–800 MW. The state governments signed many PPAs with private coal-fired plants ranging from Rs. 3.0 to 4.5 per kWh. The plant load factors can be achieved up to 80-85%. The plant load factor is simply the ratio of actual power generation over a period (typically a year) divided by the installed capacity.

Selection of Super or Ultra-Supercritical Technology

To reduce emissions such as SO2, and CO2 selecting super or ultra-supercritical technology for firing coal; this technology offers emission reduction due to coal quantity reduction and lower heat rate. Benefits in the three interrelated areas that mean the most to plant owners and operators today are improved efficiency, reduced emissions, and lower operating costs. While supercritical (SC) or ultra-supercritical (USC) units cost more than comparably sized subcritical units, the larger initial capital investment can be offset by the life cycle savings yielded by the technology due to its higher steam temperature and pressure parameters that are given in Table 1.

Even though India is withdrawing incentives for renewable energy projects and instead signing long-term contracts to buy more coal-fired power generation. Coal power facing load flexibility of baseload generating units to accommodate renewable energy is a major challenge in India, where power generation predominantly comes from coal. Currently, load dispatch centers are looking for a nominal MW output level that is achievable without needing costly support fuel (oil or natural gas) or a steam turbine bypass system, without compromising the safety and reliability of the thermal plant equipment, and with low emissions. Low load or technical minimum operation may not be ideal in terms of efficiency and performance.

The following key areas should be addressed by power plants:

- Operating power plants at 45-50% minimum load for short durations, mostly daytime

- Ramping up/down or cycling a unit from minimum load to full load

- Plant reliability, availability, and stability

- Flexible operation with multiple units

- Thorough analysis of coal characteristics, multi-coal operation, and its impact

- Plant equipment operating practices and optimization

- Controls tuning for combustion & flame stability during low-load operation without oil support.

- Reviewing fuel igniters, flame scanners, mill combinations, automatic generation control, and modes of operation

- Coal additives for combustion support and minimizing emissions

Boiler key parameters for low load or minimum technical load operation

The unit should be operated in sliding pressure mode to achieve proper low or technical minimum load with flame stability. The mill inlet PA temperature should be > 270°C with 8-15% moisture coal. Operating ranges from 45% to 100% TMCR for the load ramp rates also need to be established. Oil igniters should be in operating condition if flame stability is an issue. Operating oxygen should be greater than 5.5% at 45-50% load operation. The SA/PA ratio depends on coal quality, corner-to-corner coal flow, coal/air ratio, aux air/fuel air damper operation, coal nozzle conditions, and pressure drop, which should all be at acceptable levels. SH/RH metal temperatures should be monitored for the entire period of low-load operation.

During low load or technical minimum operation, the condenser back pressure can be high, leading to high exit velocity of the steam. This phenomenon leads to LP turbine blade erosion.

Optimum plant load operation

Cyclic operation increases the concern for creep fatigue damage caused by thermal stresses, especially in units designed for base load operation. Thus, it is essential to implement optimal load operating conditions. These include following well-established operating procedures and operating the unit with a low load (45-50 percent load). To operate the power plant at optimum load, operations and maintenance (O&M) teams need to focus on the following:

- Ensure plant availability > 95%

- Operate plant load factor > 60% (cyclic operation)

- Optimized unit heat rate < 2,300 Kcal/kWh (subcritical units) and < 2,200 Kcal/kWh (supercritical units)

- Reduce oil consumption for start -up or support low load operation.

- Minimize auxiliary power consumption.

- Load cycling up to technical minimum (as per OEM’ recommendation)

- Load ramp rate of 3-5 MW/minute (unit size-specific).

- Low load operation – 50% load with flame stability

- More number of mills in operation at low load & ability to ramp the load

- Use of plasma burners at low load for flame stability as well as reducing support oil consumption

Coal blending to reduce variable costs

The objective of coal blending is to incur economic benefits. Blending or separately firing two different varieties of coal results in a change in the aggregate quality of coal to be fired. The main characteristics of coal that affect boiler performance are the FC/VM ratio, the gross calorific value (GCV), HGI, and ash content. Indian power boilers are designed for high ash coal, and the GCV of the coal used therein is typically around 3,200-3,800 Kcal/kg. Recent trends indicate that utilities insist OEM design the boiler to handle India and imported coal with different coal characteristics.

| Unit | Description | Unit | Benefit |

| Supercritical (SC) – 660 MW | |||

| 1 | Plant Efficiency | % | 38-42 |

| 2 | CO2 Emission Reduction | % | 3-5 |

| 3 | Coal Savings * | % | 2.5 -3 |

| Ultra-Supercritical (USC)- 800 MW | |||

| 1 | Plant Efficiency | % | 42-44 |

| 2 | CO2 Emission Reduction | % | 6-8 |

| 3 | Coal savings * | % | 4 – 4.5 |

*Heating value and cost of coal same as both units

Table 1: Coal Power (Super / Ultra-Supercritical Technology)

Installation of Solar Power

One megawatt solar power plant costs fall in the range of Rs. 3 to 4 crores. Solar plants are profitable in India, especially when cheaper dry land price (4 acres/MW) is available. Component and equipment quality, system size and capacity, labor cost, grid connectivity, battery storage systems, monitoring systems and government subsidies are the factors that determine the solar power plant setup cost.

| Item | Description | Unit | Solar Power | Coal Power |

| 1 | Installed capacity | MW | 660 | 660 |

| 2 | Capital Cost | Crores | 2640 | 3300 – 4000 |

| 3 | Capacity Factor | % | < 30 | 80-85 |

| 4 | Cost of generation | Rs / kWh | < 2.0 | 3.0 – 3.5 |

| 5 | PPA Cost | Rs / kWh | 2.5 – 3.5 | 3.5 – 4.5 |

| 6 | Land Required (If it is installed on the land) | Acres | 2640 | 330 |

| 7 | O&M cost | Rs /kWh | 0.5 < | <1.0 |

| 8 | Plant Life Estimated | Years | 20-25 | Up to 35 |

| 9 | Population Density in India (Ave) | Persons / kM^2 | 492 | 492 |

Table 2: Solar Power VS. Coal Power (Super / Ultra-Supercritical)

In regions where abundant sunlight is available, solar panels run with high efficiency in these areas, producing more solar energy. Solar subsidy is not available for industrial or commercial use. However, businesses can benefit from a tax rebate if they switch to solar energy. The plant load factors can be achieved up to 22-30%.

Currently, India is largely focusing on solar power with an installation cost of anywhere from Rs.3.5 to 4.5 Cr per MW with 4.0 acres of land/MW if it is installed on the land. The government entity is willing to provide PPAs ranging from Rs. 2.50 to 3.5 per unit. The variable cost for solar power generation is virtually negligible. Fortunately, solar energy has many distinct advantages are:

⮚ Fuel cost virtually negligible

⮚ Easy maintenance

⮚ Longer lifetime (maturity needs to be demonstrated)

⮚ Decreasing cost of generation

⮚ Environmentally beneficial.

Solar Power Limitations

The capacity factor of solar energy is one of the lowest when compared to all other forms of power generation. An inherent limitation of the capacity factor comes from its requirement of daylight, preferably with a sun unobstructed by clouds, smoke, or smog and shade from trees, mountains and building structures. The rated power output of solar panels typically degrades at about 0.5% per year. The lifespan of a modern solar panel is far longer than the 20-25 years that project developers use to calculate life cycle costs.

The more weather and wind the solar panels are exposed to, the faster they will degrade. Solar power also has a limitation for sustainable power 24x 7 and the plant occupies a land area four times that of the coal power. Refer Table 2, Solar power plants occupy a land area 4 times that of the coal power plants, where India’s population density is higher (492 Persons/kM^2) compared with economically developed countries, including China (151 persons/kM^2).

Conclusion

Even though renewable energy penetration is in full swing in India, base load coal-fired power plants are added with cyclic operations, running at technical minimum loads for extended periods when the load demand is low and to maintain state load dispatch center merit orders.

Profitable and reliable coal-based power operations have become challenging in the power industry due to an increase in the coal cost, coal quality variation, and critical boiler equipment conditions, including condensers, air preheaters and mills. Solar power can cause additional burden to coal-based power plants due to debating the unit and operations at the technical minimum or below level at 45-50% MCR load. Technical minimum or low-load operation impacts plant reliability and availability of equipment because of frequent start-ups and shutdowns and greater risk for rubbing, fretting, tearing and overheating of boiler components. Optimized operations are thus necessary to reduce stakeholders’ financial liability risk.

Overall, to meet future energy requirements, the coal-based power capacity factor is expected to increase to 70-80% levels and continue to play a key role for the next couple of decades. While supercritical technology or larger-sized units have partially addressed emission requirements for SO2 and NOx and CO2, an increase in tariffs would be needed to support meeting stringent emission control standards. However, coal power has an advantage for sustainable 24×7 power supply.