Rosatom, the Russian State Agency for Atomic Energy, has signed an agreement to introduce 3D metal printing in Kyrgyzstan hydropower sector, marking a significant step toward localized manufacturing of critical equipment for power generation facilities.

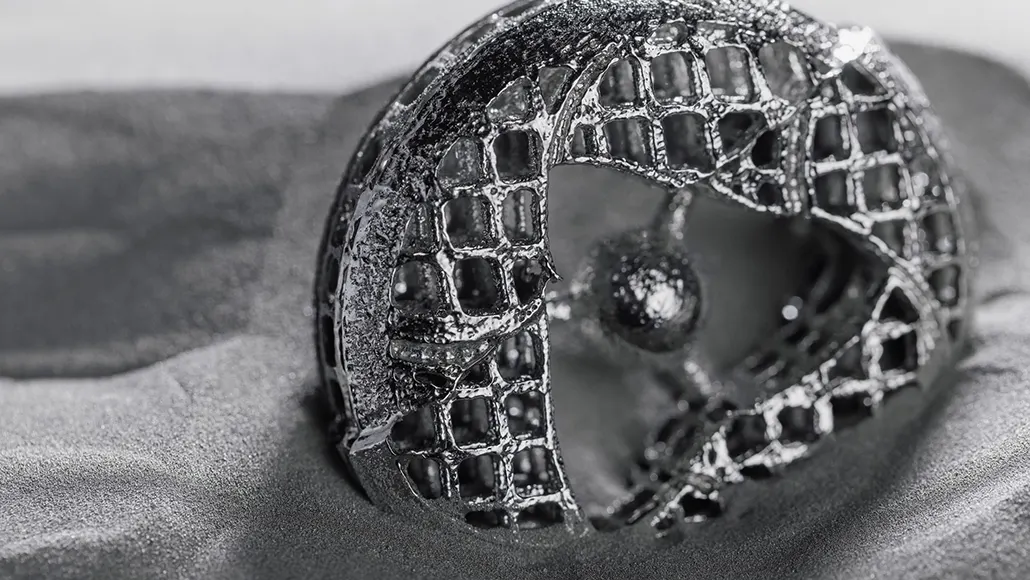

Signed in Bishkek, Kyrgyzstan, the agreement concerns components for new and existing hydropower plants created through metal additive manufacturing. This method will benefit small and medium sized hydropower plants that only require low production volumes, and have traditionally relied on costly and lengthy manufacturing processes.

Ilya Kavelashvili, director of the Additive Technologies business direction within Rosatom’s Fuel Division, said the corporation possesses the resources and technical expertise required to support a full-cycle additive manufacturing process. He also pointed to Rosatom’s experience in building regional additive manufacturing networks and delivering international projects.

The collaboration brings together Rosatom’s Additive Technologies division, the Kyrgyz-Russian Slavic University, Rosatom’s local office in Kyrgyzstan, and engineering firm Boka Hydro KG. As part of the initiative, a hydropower-focused project office has been established at the university.

The first phase of the project will concentrate on feasibility studies and technical documentation for small and medium hydropower plants. University students will be involved in the work to gain hands-on industry experience while completing their studies.

The use of additive manufacturing has already proven effective in hydropower applications, helping reduce production lead times and improve supply chain efficiency. By localizing production through 3D metal printing in Kyrgyzstan hydropower sector, the project aims to strengthen domestic manufacturing capabilities and improve long-term operational resilience.