The digital transformation of the oilfield sector, particularly in drilling operations, has shifted from a theoretical promise to a daily reality. Artificial intelligence (AI) now plays a persistent role in optimizing work that once depended largely on human experience and labor. While oilfield drilling remains a technically demanding and high-stakes activity, the presence of AI-driven systems is reducing uncertainty, boosting productivity, and opening new paths for operational consistency. Efficiency is no longer just about faster drilling; it is about achieving safer, smarter, and more cost-effective results.

Within oilfields, integrating AI systems has brought significant evolution to traditional drilling workflows. Predictive models and machine learning algorithms sift through massive volumes of operational data that daily drilling generates, such as rig sensor readings, subsurface measurements, and equipment performance statistics. These systems do more than simply collect information for operators to review later. AI processes data in real time, highlighting optimal drilling parameters and suggesting precise adjustments to steer the bit, balance rotational speed, and manage drilling fluid properties as conditions change below ground. Decisions that previously relied on manual intervention are shifting to automated platforms, which aim to sustain maximum efficiency while minimizing error.

In practical terms, this means AI can preemptively detect shifts in rock hardness or changes in pressure, quickly adapting drilling behaviour in ways that help maintain a consistent workflow. By automating the fine-tuning of operations, AI reduces unproductive time and supports higher-quality wellbore placement. Drilling teams, once siloed by the limits of on-site communication and delayed reporting, now benefit from integrated data environments that enable immediate coordination and analysis across teams in different locations.

Real-Time Data Integration and Drilling Optimization

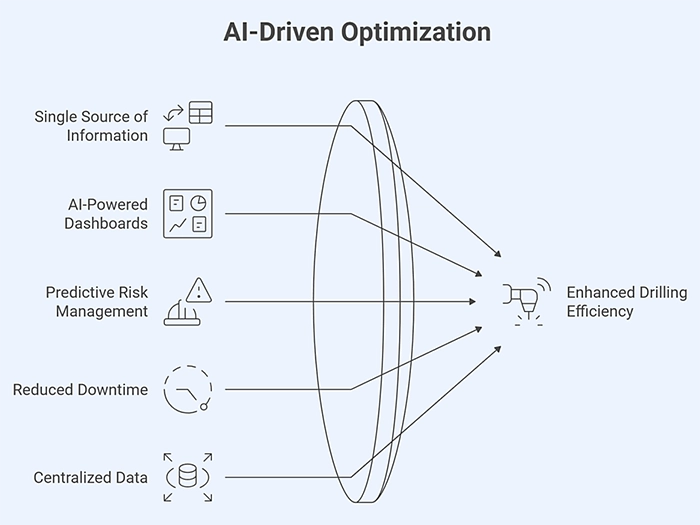

One of the most meaningful advances in AI integration in oilfield drilling is the use of real-time data integration supported by AI. Modern drilling involves dozens of systems, from rig-based sensors and tools that measure drilling dynamics to cloud-connected platforms that store and process this information. When data remains fragmented or delayed, drilling efficiency takes a measurable hit.

With AI-driven real-time integration, raw data from various sources is continuously aggregated, standardized, and synchronized over unified digital platforms. This creates a single source of truth, available on demand for managers, rig operators, and remote engineering teams alike. Visualization dashboards powered by AI help teams monitor the progress of drilling operations, flagging anomalies the moment they arise. Instead of finding out about equipment malfunction or wellbore instability after the fact, AI platforms predict and prevent these risks in real time, drastically reducing non-productive time and costly work stoppages.

Centralized data accelerates cross-team collaboration and decision-making. For example, remote operators and engineers can intervene instantly from afar, offering solutions the moment anomalies surface. As a result, the line between field and office decision-making becomes far less rigid, fostering faster problem-solving that supports both safety and performance.

Automation, Predictive Maintenance and Safety

Automated drilling systems extend AI’s reach beyond analytics and optimization, turning prescriptive recommendations directly into action. Machines can now carry out much of the drilling process themselves, reacting to sensor inputs and machine-learned cues without waiting for human oversight. These smart rigs automatically adjust torque, mud pressure, and bit direction as the environment shifts, a benefit that not only increases speed but also reduces the risk of costly downhole dysfunctions.

Perhaps even more transformative, predictive maintenance powered by AI changes how oilfield assets are managed and serviced. Equipment in the field is subject to constant wear and tear, with failures often leading to lengthy and expensive unplanned downtime. AI applications trained on enormous volumes of sensor data can forecast degradation and signal the need for servicing days or even weeks ahead of what traditional schedule-based maintenance would permit. Operators intervene only when necessary, extending the useful life of machinery and keeping rigs in service longer.

Safety also improves as AI systems provide early warnings of unsafe conditions. By monitoring diverse data streams such as temperature fluctuations, pressure changes, or the presence of hazardous gases, AI can trigger alerts the instant deviations arise, allowing teams to act before dangerous incidents occur. The result is a measurable reduction in workplace accidents and a more consistent standard of safe operation.

Business Impacts and Industry Efficiency

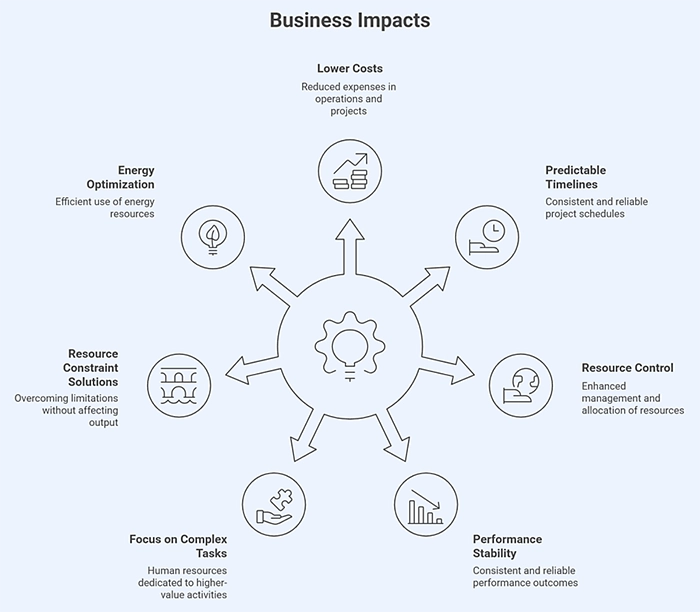

For oilfield companies, the implications are substantial. AI integration drives operational excellence but is also closely tied to bottom-line improvement. A faster, leaner drilling process translates to lower operational costs, more predictable project timelines, and greater control over resource utilization. In intensely competitive landscapes, where the economics of oil production are often challenged by market volatility, every percentage improvement in efficiency yields direct financial benefits.

By consistently standardizing best practices through AI automation and analytics, firms reduce variability in performance, a frequent challenge during periods of increased rig activity or when tapping into new and unfamiliar fields. This uniformity enables firms to scale their operations quickly while maintaining a high level of safety and quality. Moreover, with AI handling routine and repetitive management tasks, human personnel are able to focus on more complex or value-added initiatives, ensuring expertise is directed where it matters most.

From a broader view, AI integration in oilfield drilling helps address resource constraints without compromising output. As the industry adapts to stricter regulations and growing environmental expectations, smarter drilling through AI also lays the groundwork for improved environmental management by minimizing wastage and optimizing energy use.

Conclusion

AI integration in oilfield drilling has progressed from an emerging trend to a vital component of contemporary energy production. By automating critical workflows, standardizing real-time data, and strengthening asset health management, it enables a level of consistency and operational control that traditional systems rarely achieve. These advances translate into measurable improvements in safety, performance, and resource efficiency, allowing operators to make faster, data-backed decisions in high-stakes environments. AI’s growing presence is redefining how drilling companies plan, monitor, and execute complex operations, ultimately setting a new benchmark for reliability and productivity in the global energy landscape.

As the energy sector confronts rising complexity, market volatility, and environmental pressures, artificial intelligence is becoming indispensable in helping companies adapt and thrive. The technology’s predictive capabilities and automation-driven precision enhance sustainability goals while reducing operational risk and human exposure to hazardous tasks. By fusing digital intelligence with human expertise, AI transforms drilling sites into smarter, safer, and more responsive systems. This shift is not just about technological adoption but about reshaping the industry’s future, ensuring oilfield operations remain resilient, efficient, and aligned with the evolving dynamics of global energy demand.