Minimizing downtime and ensuring operational continuity have become top priorities for modern energy plants. Advanced cable protection systems constitute a frontline strategy in achieving these goals by enhancing energy reliability, improving safety, and extending the lifespan of critical electrical infrastructure. Today’s robust cable conduits, modular protection solutions, and predictive monitoring technologies are reshaping how energy plants defend against failure modes and maximize equipment uptime.

Why Downtime Matters in Energy Plants

Downtime in energy generation—whether due to cable failure, mechanical damage, or environmental exposure—results in significant financial losses, threatens energy reliability, and can trigger cascading failures throughout interconnected systems. As a result, power producers are increasingly investing in advanced cable protection systems designed specifically for the unique needs of renewable and conventional energy facilities.

Unprotected or poorly managed cables represent major sources of both operational risk and potential workplace safety incidents. Cables in energy plants must withstand mechanical load, abrasion, vibration, chemical exposure, thermal stress, and—in many locations—extreme weather, solar radiation, or even rodent activity. A failure in these systems can halt production, jeopardize worker safety, and incur costly repairs.

Innovations in Advanced Cable Protection

Next-Generation Cable Protectors

New outdoor cable protectors leverage high-performance materials such as heavy-duty polyurethane, reinforced polymers, and engineered elastomers to deliver exceptional mechanical resilience and weather resistance. Some offer modular, interlocking designs that provide bespoke adaptation to cable dimensions, load scenarios, and frequent system reconfiguration needs—crucial for both fixed and temporary power applications.

Key advancements include:

- Integrated IoT sensors in cable protectors for real-time condition monitoring (detecting wear, temperature changes, or moisture ingress).

- Enhanced load-bearing models supporting heavy vehicle traffic or industrial machinery movement without structural compromise.

- Modular designs to efficiently re-route or scale systems as infrastructure evolves.

Smart cable protectors equipped with sensors enable predictive maintenance, alerting operators before failures can occur, greatly reducing unplanned downtime.

Protective Conduit Materials

Cable protection now routinely involves the deployment of high-specification conduit systems built to excel in harsh and variable energy plant environments. These include:

- Galvanized steel conduits for fire and crush resistance.

- Stainless steel, prized for superior corrosion resistance in chemical or marine-adjacent settings.

- Fiberglass reinforced plastic (FRP), combining low weight with premium mechanical and chemical durability.

- Advanced thermoplastics and PVCs, offering flexibility and moisture/hydrocarbon resistance.

These innovations ensure that cable routing maintains structural and electrical integrity, guards against hazardous ingress, and can be quickly adapted or replaced for maintenance—crucial for uptime and plant safety.

Monitoring, Diagnostics, and Asset Management

Condition-based and predictive monitoring sit at the heart of downtime reduction. Embedded fiber optic sensors and distributed temperature sensing technologies provide continuous readouts of cable health—instantly detecting thermal hotspots, overcurrent risks, or insulation degradation.

The rollout of artificial intelligence and machine learning further augments cable management by predicting wear patterns and optimizing maintenance cycles. Such data-driven maintenance minimises operational interruptions, allows preemptive repairs, and extends both cable and protection system service life.

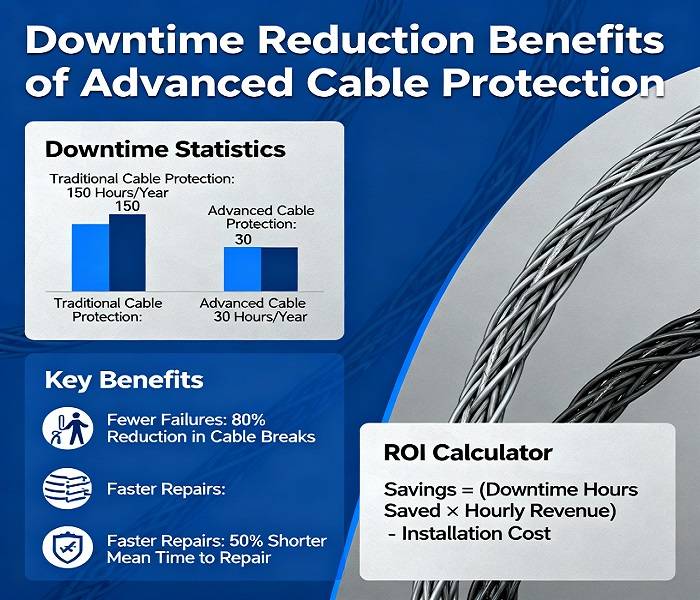

Benefits of Systematic Cable Protection

- Reduced Downtime: Smart monitoring and modular design enable predictive maintenance and rapid fault isolation, drastically shortening repair timelines versus traditional manual inspections.

- Labor and Cost Efficiency: Automated alerts, modular repairs, and less frequent maintenance mean reduced labor hours, lower operational costs, and increased asset longevity.

- Safety Enhancements: Robust protection and early warning sensors safeguard staff from electrical hazards and secondary risks posed by failed or exposed cables.

- Regulatory Compliance: Adherence to the latest standards for cable safety, fire-resistance, and environmental protection helps avoid regulatory penalties and reputational damage.

Future Trends and Outlook

The future of cable protection is shaped by next-gen materials (such as bio-insulating polymers and self-healing composites) and smarter integration with plant digitalization initiatives (IIoT, cloud-based diagnostics, automated asset management). These trends promise even stronger alignment with sustainability targets and reduced total cost of ownership in the years ahead.

Energy producers who invest in advanced cable protection not only bolster system reliability and plant productivity but also position themselves at the cutting edge of sustainable, safe, and resilient electricity generation. With the ongoing proliferation of renewable energy, automation, and digital control, robust cable management solutions will remain central to minimizing downtime and future-proofing power plants against next-generation risks.