The world’s mission to decarbonize power infrastructure and fight climate change has put green hydrogen as a bridgehead to a cleaner future. Green hydrogen, which is made by cracking water molecules into hydrogen with renewable electricity via electrolysis, is a zero-carbon fuel substitute for fossil fuels in various industries. Among the solutions in the works to speed its adoption is creating Modular Electrolyzer Parks on decommissioned industrial sites. This strategy takes advantage of available industrial infrastructure and the inherent scalability of modular technology in order to quickly deploy hydrogen production capability.

Concept Unpacked: Modular Electrolyzer Parks

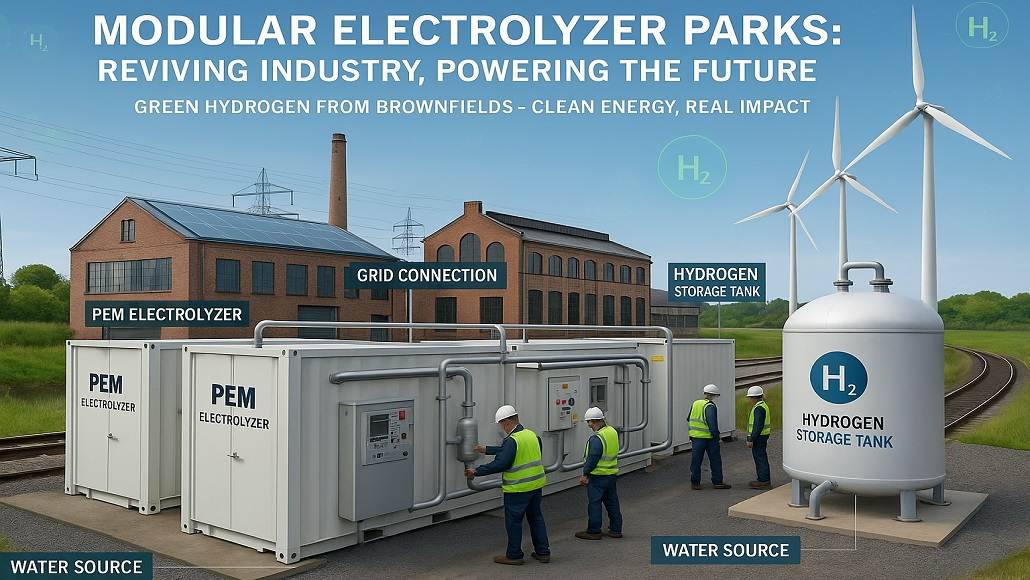

In reality, a Modular Electrolyzer Park on a converted brownfield former factory site represents a strategic intersection of advanced clean hydrogen production technology with land and infrastructure capacity. This intersection has certain benefits, which are critical to the rapid development of the new green hydrogen economy.

- Modular Electrolyzers: These are systems characterized by their pre-fabricated, standardized modules that can potentially be pre-assembled off-site and then transported and installed rapidly. The modularity has the following distinct benefits:

- Scalability and Flexibility: A plant can be established incrementally, by incorporating additional modules as demand increases or renewable energy inputs become more available.

- Reduced Construction Time and Cost: Off-site construction eliminates the on-site labor force and extremely complicated involved civil works, and thus shorter deployment time and possibly lower capital costs compared to mass-produced, special-purpose plants.

- Rapid Response Capability: Technologies such as Proton Exchange Membrane (PEM) electrolyzers enable rapid start-up and shut-down operation, best suited for direct coupling with intermittent renewable sources such as solar and wind energy.

- Standardization: Enables easy maintenance, spare part control, and training to operate, leading to successful long-term operation.

Decommissioned Industrial Sites: These are closed-down industrial or power production complexes that are not in active production. Retirement of coal energy production complexes, closed-down manufacturing complexes, or even retired oil and gas processing facilities are examples. These facilities are supposed to have present useful assets:

- Grid Connection: Typically, there is high-capacity electric transmission present, which is the utility that can supply energy-intensive electrolysis. Reusing these connections as a retrofit saves costs significantly.

- Water Accessibility: Spatial proximity to water sources (river, lake, industrial water treatment plant) to deploy electrolysis. If fresh water could be used, so much the better; research is also underway to desalinate seawater in an economically viable manner for coastal deployment.

- Transportation Network: Potential use of existing networks of roadways, railroads, or pipelines to facilitate transportation of equipment and, not incidentally, resulting hydrogen or by-products thereof (e.g., ammonia, methanol).

- Trained Workforce: An inventory of locally resident industrially trained manpower, which can make it less difficult for the labor force in sunset industries to shift toward the green economy and to have a balanced transition.

- Zoning and Permitting: Typically, they are already zoned industrially, which can speed up environmental permitting procedures than building greenfield sites, cutting down project lengths by years.

The combination of modularity and brownfield development is a frontrunner in speeding up the rollout of green hydrogen.

Spurring Economic Development and Community Revitalization

The economic advantages of building modular electrolyzer parks on former sites have a two-pronged benefit for developers and residents in both Europe and North America.

In the US, in August 2022, the government signed into law the Inflation Reduction Act (IRA), which has given huge incentives for clean technology, including a production tax credit for clean hydrogen (45V), which can bring down the cost of green hydrogen by a humongous figure. This credit provides an incentive of as much as $3 per kilogram of low-carbon hydrogen. This policy incentive is a potent driver of investment and project development. The creation of regional Hydrogen Hubs nationwide is a beacon of hope to catalyze job growth. As it redirects old industrial sites to these plants and can retain highly skilled workers in declining industries, providing a good transition for employees, and restoring local economies.

They are engineering, manufacturing, logistics, and maintenance positions. The European Clean Hydrogen Alliance and RePowerEU, among others, are investing a huge public sum in hydrogen projects, once again energizing economic growth. For instance, the EU has recently agreed to fund part of €992 million (nearly €1 billion) for 15 renewable hydrogen projects in 5 nations from the European Hydrogen Bank’s first auction, producing 1.1 million tonnes of renewable hydrogen over a decade and avoiding more than 11.8 million tonnes of CO2 emissions. The strategic importance of hydrogen in industrial decarbonisation, particularly in steel and fertilizer manufacturing, is behind investment in making industry more competitive and resilient.

Apart from directly generating jobs, recycling brownfield land to produce green hydrogen promotes urban-industrial symbiosis. It is a green growth strategy that promotes the most optimal use of resources and minimization of waste within the urban and industrial environment. By putting new clean industries on existing developed brownfield sites, it does not need to develop virgin greenfield sites, thus lowering environmental footprints and in most cases, promoting supply chain resilience improvement through geographic proximity to existing industrial clusters.

Environmental Value

The environmental advantage of green hydrogen is clear: it emits no greenhouse gas when made and, when consumed, provided that it is powered by renewables. Utilizing electrolyzer parks on retired land adds a further environmental burden by revitalizing potentially degraded or underutilized land as productive clean energy assets.

Regulatory Framework

EU environmental policy is leading the way in framing and promoting the environmental purity of green hydrogen. Commission Delegated Regulations (EU) 2023/1184 and 2023/1185, which took effect in June 2023, provide a comprehensive framework to calculate life-cycle GHG emissions of renewable hydrogen with at least 70% GHG savings against fossil fuel alternatives. These are conditions defining regulations such as “additionality” (a new source of renewable energy to be introduced for the hydrogen production), “temporal correlation” (correspondence between hydrogen production and hourly blocks of renewable electricity starting from 2027), and “geographic correlation” (site of electrolyzer near renewable source).

The European Union Renewable Energy Directive III (RED III) likewise sets ambitious targets for the production and consumption of renewable hydrogen, to account for 42% of industrial hydrogen use from renewables by 2030, to 60% by 2035.

Construction of hydrogen production plants in North America, the United States most notably, is subject to a dizzying labyrinth of federal, state, and city environmental, safety, and building codes. The Environmental Protection Agency (EPA) demands pre-construction New Source Review (NSR) permits for factories emitting regulated air pollutants, and environmental impact assessments are being mandated. While less aimed at retired facilities, the law would remain in force, the benefit being that there are many brownfield sites which have a pre-existing environmental profile already present, which can be audited and remediated during redevelopment, possibly minimizing aspects of environmental analysis relative to greenfield sites still in unused condition.

Key Technologies

The market for electrolyzers is on record growth due to decarbonization across the world and technological innovation. Three leading technologies dominate the market currently:

- Alkaline Electrolyzers: It is the most mature and market-validated technology, whose ruggedness, reduced capital cost (previously), and an established value chain. These are typically favored for massive-scale, steady-state hydrogen production.

- Proton Exchange Membrane (PEM) Electrolyzers: They are increasing their market share with their high energy efficiency, small size, and fast reaction to fluctuating renewable energy inputs, but also come with the wonderful benefit of ramping up and down. They may be directly inserted into the fluctuating solar and wind power flows and plugged in directly. But they will generally have a greater capital cost as they involve the use of precious materials such as iridium and platinum.

- Solid Oxide Electrolyzer Cells (SOEC): The most efficient of the high-temperature electrolyzers, particularly where waste process heat is readily available, as it decreases the amount of electrical energy input needed. They are thus very desirable to be located alongside steelworks, chemical works, or cement works.

Market Trends

The global green hydrogen market will experience massive growth. Forecast anticipates the global green hydrogen market to be USD 386.6 billion in 2032 and will progress with a massive CAGR of 51.5% during 2023-2032.

The Future Vision: A Pillar of Decarbonization

Modular Electrolyzer Parks on vacant land is a nice and believable means to speed up the transition to a clean hydrogen economy.

Due to technological innovations and established policy regimes, the parks will, in turn, redevelop old industrial estates into hubs of clean energy production. Not only will they hold emissions in hard-to-abate sectors such as heavy industries (steel, chemicals) and transport (shipping, aviation, heavy road transport), but also contribute to energy security by means of diversification of energy supply and decreased dependency on fossil fuels. Strategic recycling of those facilities is a circular economy strategy, converting liabilities into assets in creating a truly sustainable and decarbonized future, both conducive to economic development and the protection of the environment.