For owners of Mitsubishi’s M501G Series turbines, it’s time to look at your actuators and servo valves. The reason is twofold. First, there is a new solution available for changing servo valves on these turbines. More on that in a moment. Second, without spare actuators and replacement kits on hand, servicing or repairing these actuators could very likely extend a planned outage. The good news, experts say, is including these items now on a list of maintenance tasks for a planned outage will wipe away concerns.

As plant maintenance teams know, the inlet guide vane actuators and fuel gas control valves on turbines regulate the ratio of air and fuel in varying loads for efficiency and minimal emissions. The fuel gas control valve on an actuator is the primary interface between a control system and the mechanical part of the plant. Maintaining that link produces power. When there is an issue with the air-fuel metering equipment, the turbine may be forced to shut down for corrective measures.

When troubleshooting an actuation system, it’s common practice to swap out the servo valve early in the process. With traditional explosion-proof systems, this requires opening the terminal box, removing wires from terminal strips, detaching conduit from the servo valve, pulling the wires through the conduit, removing hydraulic connections, and finally removing the servo valve from the manifold. The reverse process is required to install the replacement servo valve.

After experiencing more than one extended outage attributable to valve replacement, the manager at a United States electric utility company’s 500-MW power plant wanted a solution for his Mitsubishi M501G turbine. The Southeast U.S. plant’s staff called Moog distributor Hydraulics & Pneumatic Sales, Inc., since the two organizations had a long-standing relationship. After a meeting between engineers and managers from the plant, HPS and Moog designed and manufactured a quick disconnect cabling system for explosion-proof servo valves, something that works on Mitsubishi turbines as well as General Electric, Siemens and other types of units. With the quick disconnect kit, a power plant technician can swap out a servo valve in 20 minutes. Moog also designed the kit to comply with National Electric Code Class I, Division 2 and ATEX Zone 2 locations.

A quick fix for servo valves leads to actuators

While developing the quick disconnect system for the plant’s servo valves, HPS realized plant managers had operated the Mitsubishi 501G turbines seven years without ever servicing the actuators; that’s two years beyond the recommended maintenance schedule. According to Matthew Payne, engineering sales territory manager at Power Systems Inc., part of HPS, his firm’s success with the quick disconnect program led him to propose that the plant’s electrical and instrumentation team overhaul the actuators.

“When the plant’s management changed, the new group wanted to take a proactive approach,” says Payne. “The conversations we had had with the E&I team got management on board.”

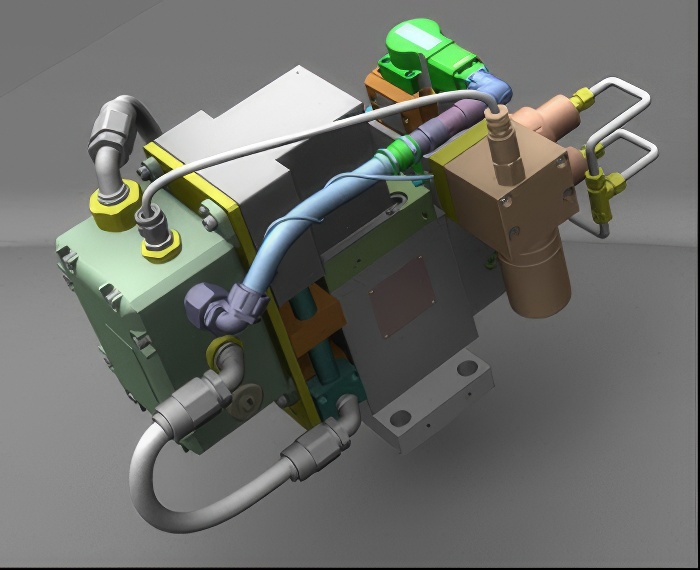

A typical fuel control valve consists of a servo-actuator bolted to a process valve with a failsafe spring cage. The process valve is bolted into the process piping via ANSI-rated flanges. The entire assembly is either removed and sent to the factory for overhaul or swapped out with a spare assembly.

In some cases, the process valve is welded into the process piping and cannot be easily removed for service. That was the case at this facility, adding to the complexity of the project, which also required a tight turnaround. According to HPS, Moog is an authorized repair center for the process valves and has the expertise to refurbish the valves in place at a customer’s facility.

Moog says it doesn’t sell its parts to third-party repair houses. So, while some plants turn to third parties for help, they would be unable to undertake actuator work with any guarantee. Moog put together a hybrid proposal outlining how it would separate the actuators from the process valves, refurbish the process valves on site, and install the spare actuators to the valves. The actuators removed from service were sent to Moog’s factory for overhaul prior to the upcoming outage season.

“You have to get ahead of planned outages by at least six months with the correct actuators, model numbers and repair kits if you’re going to carry off a smooth replacement within the usual two-week planned outages that plants schedule,” says Steve Beddick, national sales manager for Moog. “If a plant has Mitsubishi turbines, all they have to do is work with our distributor and send us a ‘project detailer’ well in advance, so we can turn around the actuators and control valves within the allowed time.”

Payne underscored with the E&I team that a Moog-authorized repair includes testing and bringing the actuator up to the latest standard, cutting back on the potential of a failure that will take the turbine offline. The Mitsubishi turbines typically have a five-year warranty, says Payne. But after five years, Payne cautions E&I teams to be diligent about maintenance. When nearing the end of the warranty period, Payne recommends overhauling the actuators and inspecting all the soft goods (e.g., O-rings, gaskets, screws, pressure switch, and filter element) for potential replacement.

The quantity of spares required depends on how managers have organized a plant and the number of turbines. For instance, if there are two 2×1 block configurations and an entire block is brought down for outage, then Beddick recommends having two complete engine sets on hand. When the process valves are welded in place, that would include two complete sets of valve repair kits as well. A plant configured as four 1×1 blocks could get by with a single engine set of spares and cycle them through each block consecutively, adds Beddick.

Plants Moog and its distributors typically visit have four to six turbines. With the recommended spares on hand, if there is a forced outage, a plant’s E&I team can have the turbine online in hours versus trying to find and replace a single actuator that could, in some cases, take months. Under normal conditions, disassembly of the actuators happens with a Moog field service technician and the plant’s personnel.

“These actuators are modified for each facility’s turbine,” notes Beddick. “Before their warranty runs out, a plant’s E&I team should review their planned outages with a distributor like HPS.”

The review should include an assessment of the actuators in the scope of the outage and a site survey to document the condition of the equipment. Putting together a proposal at least eight months in advance ensures that a plant can submit any purchase order well before each scheduled outage.

For any plant running Mitsubishi M501G turbines, the E&I team should consider three things:

- Add quick disconnect servo valves to the turbine. Plants can find a Moog distributor here.

- Review the major inspection strategy; determine the number of spare engine sets required.

- Discuss preventive maintenance with a distributor 12 to 18 months before a planned outage.

Trying to rein in costs causes some plant managers to consider working with an unauthorized repair house. But Beddick cautions that short-term savings only incur costs down the line such as an emergent issue with a component or unplanned outage.