The energy industry operates under some of the most stringent safety and compliance requirements of any industrial sector, reflecting the critical importance of reliable electrical infrastructure in modern society. With power systems becoming increasingly complex and interconnected, the role of energy cabling safety compliance has expanded far beyond basic electrical protection to encompass comprehensive risk management across diverse operating environments. Modern energy facilities must navigate an intricate web of international standards, national regulations, and industry-specific requirements that govern every aspect of cabling system design, installation, and maintenance.

Regulatory Framework and Standards Landscape

International Standards Foundation

The International Electrotechnical Commission (IEC) provides the fundamental framework for energy cabling standards worldwide, establishing comprehensive specifications that ensure global compatibility and safety. IEC standards encompass critical areas including cable construction requirements, fire performance characteristics, environmental resistance specifications, and electrical performance parameters that form the foundation of modern energy cabling systems.

IEC 60502 standards specifically address power cables with extruded insulation for rated voltages from 1 kV to 30 kV, providing detailed specifications for cables commonly used in energy distribution systems. These standards establish requirements for conductor materials, insulation systems, protective sheaths, and accessories that ensure reliable performance across diverse operating conditions. The comprehensive nature of these standards reflects the critical importance of cable reliability in energy infrastructure applications.

Fire safety requirements under IEC standards address multiple critical aspects including flame propagation resistance, smoke emission characteristics, and toxic gas generation during combustion. IEC 60332 series standards establish test methods for assessing cable fire performance, while IEC 60331 addresses circuit integrity maintenance under fire conditions. These standards recognize that energy facility fires present unique challenges where maintaining electrical system functionality can be critical for safe facility shutdown and emergency response.

National and Regional Implementation

Countries worldwide have adapted international standards to address specific regional requirements and operating conditions. In India, the Central Electricity Authority (CEA) and Bureau of Indian Standards (BIS) establish comprehensive requirements for energy cabling systems that reflect both international best practices and local environmental conditions. These national standards address specific challenges including monsoon exposure, extreme temperature variations, and seismic considerations that affect energy infrastructure performance.

European standards under the EN designation provide detailed implementation guidelines for IEC requirements while addressing specific regional considerations. EN 50200 establishes requirements for fire-resistant cables used in emergency circuits, while EN 50363 addresses insulating materials for low voltage energy cables. The harmonization of European standards facilitates cross-border energy infrastructure development while maintaining stringent safety requirements.

The United States implements energy cabling requirements through the National Electrical Code (NEC) and related standards that address specific American operating conditions and regulatory requirements. Recent updates to electrical safety standards in various countries reflect evolving understanding of energy system risks and the need for enhanced protection in modern high-density installations.

Fire Safety and Circuit Integrity Requirements

Advanced Fire Performance Standards

Modern energy facilities demand cabling systems that maintain functionality even under extreme fire conditions. Circuit integrity requirements ensure that critical systems including emergency lighting, fire suppression, and communication systems remain operational during fire emergencies. These requirements have become increasingly stringent as energy facilities have grown in size and complexity.

Fire-resistant cables must demonstrate the ability to maintain electrical continuity when exposed to standardized fire conditions including specified temperatures, flame exposure duration, and mechanical stress Testing protocols simulate real-world fire conditions including both direct flame exposure and elevated ambient temperatures that might be encountered during facility fires.

Halogen-free cable formulations have become standard in many energy applications to minimize toxic gas generation during fire conditions. These advanced formulations maintain excellent electrical performance while significantly reducing the health risks associated with cable combustion products. The development of bio-based insulation materials further advances both fire safety and environmental sustainability objectives.

Emergency System Protection

Energy facilities increasingly require specialized protection for emergency and safety systems that must remain operational under all conditions. Fire-resistant cable systems for these applications must meet enhanced performance standards that exceed those required for general power distribution. These systems often incorporate multiple protective layers including fire-resistant insulation, protective sheaths, and armoring systems.

Advanced fire detection and suppression systems in energy facilities rely on cable systems that maintain integrity even when exposed to the suppression agents themselves. Cable systems must demonstrate compatibility with various suppression methods while maintaining electrical performance throughout emergency conditions.

Environmental and Chemical Resistance Standards

Harsh Environment Performance Requirements

Energy facilities operate in diverse environments that present unique challenges for cabling systems. Coastal installations must address salt spray exposure, while industrial facilities may encounter chemical vapors and contaminated soils. Cabling standards address these challenges through comprehensive environmental resistance requirements that ensure long-term performance.

Chemical resistance testing protocols evaluate cable performance when exposed to common industrial chemicals including acids, alkalis, solvents, and petroleum products. These tests simulate both direct contact and vapor exposure conditions that cables might encounter during normal operation or emergency conditions. The results inform material selection and installation practices that ensure reliable performance throughout system lifetime.

Corrosion resistance requirements address both atmospheric and direct exposure conditions that affect cable performance over time. Advanced testing protocols evaluate long-term performance under accelerated aging conditions that simulate decades of environmental exposure in compressed timeframes.

Underground and Underwater Applications

Energy infrastructure increasingly utilizes underground and underwater cable installations that present unique environmental challenges. Underground installations must address soil chemistry variations, groundwater exposure, and potential contamination from adjacent industrial activities. Standards address these challenges through comprehensive requirements for cable construction, installation practices, and long-term monitoring.

Moisture protection requirements for underground installations recognize that even minor water ingress can compromise cable performance over time. Advanced sealing systems and water-blocking technologies ensure that underground energy cables maintain performance even when subjected to hydrostatic pressure and prolonged moisture exposure.

Testing and Certification Protocols

Comprehensive Performance Validation

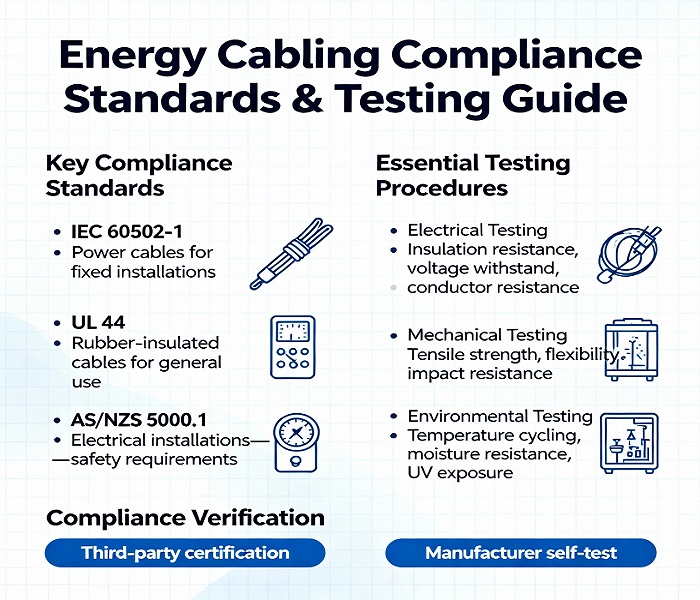

Modern energy cabling systems undergo extensive testing protocols that validate performance across all relevant operating conditions. Electrical testing verifies insulation resistance, conductor integrity, and voltage withstand capabilities under both normal and fault conditions. These tests ensure that cables can safely handle both operational loads and abnormal conditions that might occur during system faults.

Mechanical testing protocols evaluate cable performance under installation stresses, operational loads, and environmental conditions that affect long-term reliability. Testing includes pulling forces, bending radii, impact resistance, and vibration tolerance that ensure cables maintain integrity throughout their operational lifetime.

Environmental testing simulates the full range of conditions that cables might encounter during service including temperature cycling, humidity exposure, chemical contact, and UV radiation. These comprehensive testing protocols provide confidence that cables will perform reliably throughout their design life even under challenging operating conditions.

Certification and Quality Assurance

Independent certification programs provide verification that energy cabling systems meet all applicable standards and performance requirements. Certification bodies conduct comprehensive evaluations including factory inspections, testing protocol reviews, and ongoing quality monitoring that ensure consistent product performance.

Quality management systems in cable manufacturing facilities implement comprehensive controls that ensure every product meets specification requirements. These systems encompass raw material qualification, manufacturing process controls, finished product testing, and traceability systems that enable rapid response to any quality issues.

Installation and Maintenance Compliance

Proper Installation Practices

Compliance with energy cabling safety standards extends beyond product specifications to encompass installation practices that ensure optimal system performance. Proper installation techniques prevent damage during installation while ensuring that cables achieve their designed performance characteristics throughout their operational lifetime.

Cable routing and support requirements ensure that mechanical stresses remain within acceptable limits while providing adequate protection from environmental hazards. These requirements address factors including support spacing, bending radii, and separation from heat sources that affect long-term cable performance.

Grounding and bonding requirements ensure electrical safety while preventing electromagnetic interference that could affect system performance. Proper grounding practices protect both personnel and equipment while ensuring that electrical systems operate as designed under both normal and fault conditions.

Ongoing Maintenance and Monitoring

Regular inspection and maintenance programs ensure that energy cabling systems continue to meet safety and performance requirements throughout their operational lifetime. These programs identify developing issues before they result in system failures while ensuring continued compliance with applicable standards.

Advanced monitoring systems now enable continuous assessment of cable condition and performance, supporting predictive maintenance approaches that optimize both safety and reliability. These systems provide early warning of developing problems while documenting ongoing compliance with performance requirements.

Future Developments in Safety and Compliance

Evolving Standards and Requirements

Energy cabling standards continue to evolve in response to changing technology, environmental conditions, and operational requirements. Recent updates address emerging challenges including cybersecurity considerations, smart grid integration, and enhanced environmental sustainability. These evolving standards ensure that energy infrastructure remains safe and reliable as technology continues to advance.

The integration of renewable energy sources creates new challenges that require enhanced standards and compliance approaches. Variable generation patterns and distributed installation locations demand new approaches to safety and reliability that are reflected in evolving standards and regulations.

Technology Integration and Smart Systems

Advanced monitoring and control technologies are being integrated into energy cabling standards to enable enhanced safety and performance management. These technologies provide real-time assessment of system condition while enabling automated responses to developing problems.

The development of self-healing materials and intelligent cable systems represents the next frontier in energy cabling safety and compliance. These advanced systems will provide unprecedented levels of safety and reliability while reducing maintenance requirements and extending system lifetime.

Energy cabling safety compliance will continue to evolve as both technology and understanding of system risks advance. The integration of advanced materials, intelligent monitoring systems, and predictive maintenance approaches will establish new standards for safety and reliability in energy infrastructure. These developments will ensure that energy cabling systems continue to provide the safety and reliability that modern society demands while supporting the transition to more sustainable and efficient energy systems.