High-Temperature Materials in Power Generation Facilities

The pursuit of increased efficiency in power generation has driven operating temperatures to unprecedented levels across nuclear, thermal, and geothermal facilities. Modern power plants now routinely operate at temperatures that challenge traditional materials and protection systems, with some advanced facilities reaching operating temperatures approaching 2,000°C in specialized applications. The development and deployment of high-temperature materials in power plants has become critical not only for efficiency optimization but also for ensuring long-term safety and reliability in these demanding environments.

Understanding High-Temperature Challenges in Power Generation

Temperature Extremes Across Power Generation Types

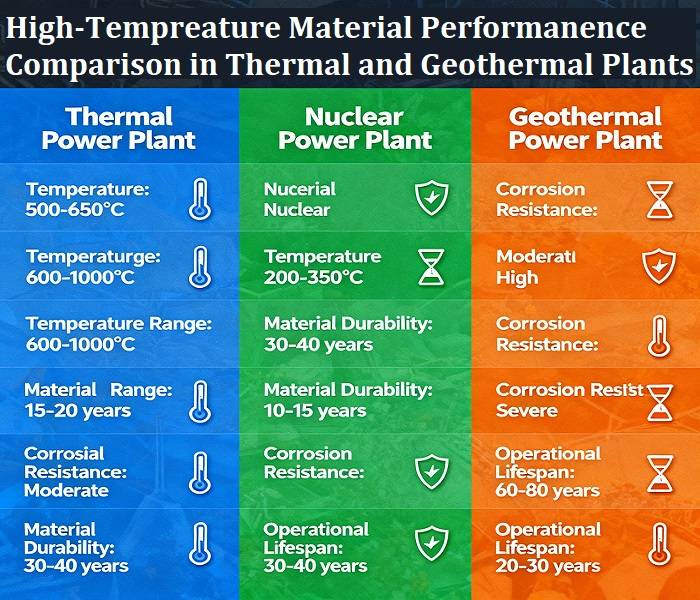

Different power generation technologies present distinct high-temperature challenges that require specialized material solutions. Nuclear power plants operate under extreme thermal conditions that demand materials capable of withstanding prolonged exposure to radiation while maintaining structural integrity at elevated temperatures. The heat pipe systems used in advanced nuclear reactors can operate at temperatures exceeding 1,700 K for lithium-based systems and 1,300 K for sodium-based systems, pushing material science to its limits.

Thermal power plants, particularly those utilizing advanced combustion technologies, create environments where traditional materials simply cannot survive. The combustion chambers and heat exchange systems in these facilities experience temperature gradients that can cause catastrophic material failure if appropriate high-temperature materials are not employed. These conditions demand materials that maintain both mechanical strength and chemical stability under extreme thermal stress.

Geothermal facilities present unique challenges where high temperatures combine with chemically aggressive environments. The combination of elevated temperatures and corrosive geothermal fluids creates conditions that rapidly degrade conventional materials. Advanced geothermal systems, particularly those operating in deep reservoir conditions, require materials that can withstand temperatures exceeding 300°C while maintaining resistance to highly corrosive mineral-rich fluids.

Advanced Material Technologies for Extreme Conditions

High-Performance Polymers and Fluoropolymers

The development of advanced polymer systems has revolutionized high-temperature protection in power generation facilities. Modern fluoropolymer systems including PTFE, FEP, PFA, and ETFE provide temperature resistance ranging from -200°C to 260°C while maintaining excellent chemical resistance and electrical properties. These materials have become essential for protecting sensitive electrical systems in high-temperature power plant environments.

Specialized polyetheretherketone (PEEK) compounds now provide mechanical strength and temperature resistance up to 250°C while offering exceptional radiation resistance, making them particularly valuable in nuclear applications. The combination of high-temperature stability with radiation resistance addresses two critical challenges simultaneously in nuclear power generation environments.

Advanced silicone rubber formulations provide flexibility and temperature resistance up to 180°C, making them ideal for applications requiring both thermal protection and mechanical flexibility. These materials maintain their protective properties even under continuous thermal cycling, which is common in power generation applications where startup and shutdown cycles create significant thermal stress.

Metallic Conduit Systems for Extreme Environments

Stainless steel conduit systems have evolved to provide unparalleled protection in the most demanding high-temperature power generation applications. Type 316 stainless steel, with its enhanced nickel content and molybdenum additions, provides superior corrosion resistance and temperature stability compared to conventional materials. These alloys maintain structural integrity and corrosion resistance across pH ranges from 2 to 12, making them suitable for diverse power generation environments.

The development of specialized nuclear-grade conduit systems addresses the unique requirements of nuclear power applications. These systems incorporate materials specifically designed to maintain integrity under combined high-temperature and radiation exposure conditions. Nuclear wiring conduits must meet stringent requirements including heat aging resistance, flame resistance, moisture resistance, low-temperature flexibility, radiation resistance, and continuous high-temperature service capability.

Ceramic and Composite Material Integration

Advanced ceramic materials have emerged as critical components in the highest temperature power generation applications. Ceramic yarn and quartz yarn braiding systems can withstand temperatures up to 600°C while providing excellent insulation properties and minimal thermal conductivity. These materials find particular application in areas where traditional protective systems would fail catastrophically.

High-temperature composite materials combining multiple protective characteristics are increasingly deployed in power generation facilities. Special high-temperature yarn systems can withstand temperatures from -72°C to 1,000°C, providing unprecedented operating ranges for protective systems. These advanced composites maintain structural integrity across extreme temperature ranges while providing chemical resistance and mechanical protection.

Application-Specific Solutions Across Power Generation Types

Nuclear Power Plant Requirements

Nuclear power facilities present the most demanding combination of high-temperature and radiation exposure conditions. Materials in these environments must maintain performance under neutron bombardment while withstanding elevated temperatures and chemically aggressive coolant systems. Advanced heat pipe materials including molybdenum-tungsten alloys provide the strength and thermal conductivity required for next-generation nuclear systems.

The development of specialized nuclear conduit systems addresses multiple simultaneous challenges including thermal stability, radiation resistance, chemical compatibility, and mechanical strength. These systems undergo extensive testing including heat aging, flame resistance, moisture resistance, and radiation exposure testing to ensure reliable performance throughout the facility’s operational lifetime.

Thermal Power Plant Applications

Coal, gas, and oil-fired thermal power plants create some of the most thermally aggressive environments in power generation. Combustion temperatures can exceed 1,500°C in advanced high-efficiency systems, requiring materials that maintain integrity under extreme thermal stress. Heat-resistant conduit systems must provide protection for critical control and monitoring cables in these demanding environments.

Advanced thermal power plants increasingly utilize high-temperature thermal energy storage systems that require specialized protective materials capable of withstanding temperatures approaching 2,400°C. These systems demand materials that maintain structural integrity and protective characteristics under conditions that would instantly destroy conventional protection systems.

Geothermal System Challenges

Geothermal power generation creates unique challenges where high temperatures combine with aggressive chemical environments. Geothermal fluids contain dissolved minerals and gases that can rapidly corrode conventional materials. High-temperature oil-resistant cables and conduits must withstand both thermal and chemical attack while maintaining electrical isolation and mechanical protection.

The expanding utilization of enhanced geothermal systems operating at greater depths requires materials capable of withstanding temperatures exceeding 300°C while providing long-term chemical resistance. These demanding conditions require specialized material formulations that combine thermal stability with exceptional chemical resistance across diverse pH ranges and mineral compositions.

Installation and Maintenance Considerations

Design Integration for High-Temperature Service

Successful implementation of high-temperature materials requires comprehensive design integration that considers thermal expansion, chemical compatibility, and maintenance accessibility. High-temperature conduit systems must accommodate significant thermal expansion while maintaining protective integrity. Advanced support systems now incorporate thermal expansion joints and flexible connections that prevent thermal stress concentration.

Multi-layer insulation systems combining different material types provide optimized protection across varying temperature zones within power generation facilities. These systems utilize layered approaches where each material contributes specific protective characteristics, creating comprehensive protection systems that exceed the capabilities of any single material.

Predictive Maintenance and Monitoring

Advanced high-temperature protection systems increasingly incorporate monitoring capabilities that provide real-time assessment of material condition and performance. Distributed temperature sensing systems utilizing fiber optic technologies can continuously monitor conduit and cable temperatures along their entire length. This monitoring capability enables predictive maintenance approaches that prevent failures before they occur.

The integration of advanced monitoring systems with high-temperature materials creates comprehensive protection and management systems. These integrated approaches provide continuous assessment of both material condition and system performance, enabling optimization of both protection effectiveness and operational efficiency.

Future Developments in High-Temperature Materials

Emerging Material Technologies

Research into next-generation high-temperature materials continues to push the boundaries of what is possible in power generation applications. Advanced nano-materials and molecular engineering approaches are creating materials with previously impossible combinations of properties. These developments promise further improvements in temperature capability, chemical resistance, and mechanical performance.

Self-healing material technologies are beginning to find application in high-temperature power generation environments. These materials can automatically repair damage caused by thermal cycling or chemical attack, potentially extending service life while reducing maintenance requirements. The integration of self-healing capabilities with high-temperature resistance represents a significant advancement in protective material technology.

Sustainable and Advanced Manufacturing

The development of sustainable high-temperature materials addresses both performance and environmental considerations. Bio-based insulation materials and recycled content formulations are being developed for high-temperature applications where environmental conditions permit. These developments support both improved performance and enhanced environmental sustainability.

Advanced manufacturing techniques including additive manufacturing and precision coating technologies enable creation of complex high-temperature protection systems with optimized performance characteristics. These manufacturing advances allow creation of custom protection solutions tailored to specific power generation facility requirements.

Economic and Performance Benefits

Lifecycle Cost Optimization

High-performance high-temperature materials, while requiring higher initial investment, provide significant long-term economic benefits through extended service life and reduced maintenance requirements. Advanced materials can operate for decades under conditions that would destroy conventional materials within months or years.

The integration of high-temperature materials with intelligent monitoring systems provides predictive maintenance capabilities that optimize both performance and cost effectiveness. These systems enable maintenance scheduling based on actual condition rather than arbitrary time intervals, significantly reducing both maintenance costs and system downtime.

Enhanced System Reliability

Modern high-temperature materials provide reliability levels that enable continuous operation under conditions that previously required frequent shutdowns for maintenance and repair. This enhanced reliability translates directly into improved power generation efficiency and reduced operational costs. The combination of advanced materials with intelligent monitoring creates protection systems that support continuous operation even under the most demanding conditions.

The future of high-temperature materials in power generation will be characterized by continued advancement in both material capabilities and system integration. These developments will enable power generation facilities to operate at higher temperatures and greater efficiency while maintaining the safety and reliability standards that modern society demands from its electrical infrastructure. As power generation technologies continue to evolve toward greater efficiency and sustainability, high-temperature materials will remain essential for achieving these critical objectives.